Compare, select, buy your pump

High-Performance 3V Mini Diaphragm Air Pump for Medical Oxygen Compressors

Customized Service

To provide customers with quality products and satisfactory service

PYP520-XA Micro Air Pump

As your dedicated OEM mini diaphragm pump manufacturer, we provide more than just hardware. Every unit undergoes a strict 100% aging test in our ISO9001-certified facility. We offer full technical support to help you calibrate the flow rate and operating voltage to match your specific application requirements.

Technical Specifications

| Technical Parameter | Performance Data by Voltage | ||||

|---|---|---|---|---|---|

| Rated Voltage | DC 3V | DC 6V | DC 9V | DC 12V | DC 24V |

| Rated Current | < 1200mA | < 600mA | < 430mA | < 300mA | < 150mA |

| Power | 3.6 W | 3.6 W | 3.6 W | 3.6 W | 3.6 W |

| Tap O.D. (Nozzle) | Ø 4.5 mm | ||||

| Air Flow (No Load) | 1.5 - 4.0 LPM | ||||

| Max Pressure | > 80 KPa (600 mmHg) | ||||

| Noise Level | < 65 dB (at 30cm distance) | ||||

| Life Test | > 500 Hours (Continuous) | ||||

| Weight | Approx. 68.0 g | ||||

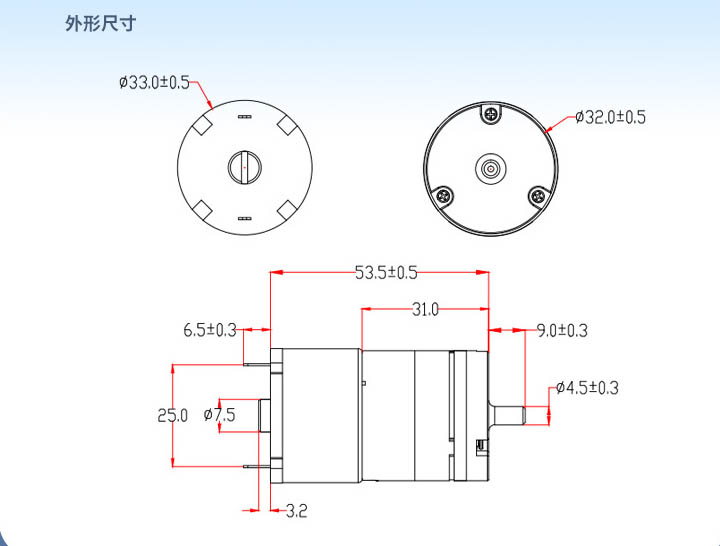

Specification Engineering Drawing

Product Applications

| Industry / Application | Specific Use Case | Why Use PINCHEHG 3V Pump? |

| Medical Devices | Portable Oxygen Concentrators (POC) | High Efficiency & Low Heat: Optimized 3V DC motor ensures extended battery life for handheld medical devices while maintaining stable oxygen flow. |

| Healthcare Monitoring | Wearable Blood Pressure Monitors | Ultra-Compact Size: Its miniature footprint allows for seamless integration into wrist-based or portable cuff devices without adding bulk. |

| Environmental Sensing | Portable Gas Detectors & Air Samplers | Precise Flow Control: Provides the consistent suction required for sensitive gas sensors to deliver accurate air quality readings in real-time. |

| Consumer Electronics | Scent Delivery & Aromatherapy Diffusers | Whisper-Quiet Operation: Advanced noise-dampening design ensures the device operates under 55dB, ideal for office or bedside environments. |

| Laboratory Automation | Microfluidic Liquid Handling (Air Drive) | Quick Response Time: The low-inertia diaphragm allows for rapid start-stop cycles, essential for precise micro-dosing and liquid movement. |

Tea table

Vacuum packing machine

Water dispenser

Foam hand sanitizer

Electric decanter

dishwasher

Manufacturing Quality & Compliance

At PINMOTOR, our manufacturing philosophy is built on the "Zero-Defect" principle. We understand that a 3V mini diaphragm air pump is often the heart of a life-saving medical device, which is why our quality management system (QMS) is strictly aligned with international standards.

ISO 9001:2015 Certified

Our quality management system ensures consistent product output, from raw material inspection to final functional testing of Every PINCHEHG series pump.

IATF 16949 Compliant

We leverage automotive-grade process discipline to guarantee ultra-low defect rates and long-term reliability in consumer electronic applications.

RoHS & REACH Fully Compliant

All materials used in Every PINCHEHG series pump—including the motor brushes, diaphragm, and housing—are free from hazardous substances, ensuring your end-product is ready for the EU and North American markets.

Manufacturing Quality & Compliance

Rigorous Testing Protocol

Every 3V micro pump is subjected to a 100% aging test and pressure stability check. Our ISO 9001:2015 certified facility ensures that each batch meets the high reliability required for medical oxygen compressors.

Regulatory Compliance

- RoHS & REACH: 100% Lead-free and non-toxic materials.

- Medical Grade: Oil-free design for clean air output.

- SGS Audited: Transparency in every step of production.

We supply more than just product, we engineer solutions optimised to suit your application requirements.