By: The Pinmotor Engineering Team | Last Updated: October 24, 2023

Fact-Checked by: Senior Design Lead, Wei Zhang

When you're designing a device that relies on fluid or gas movement—whether it's a medical monitor or an industrial inkjet printer—the diaphragm pump is the "heart" of your system. If the heart stops, the whole machine fails.

At Pinmotor, we’ve spent years in the lab testing thousands of pump cycles. We've seen exactly where designs fail and where they excel. This guide breaks down the core components of diaphragm pump design and shares the "pro-tips" we’ve learned from real-world engineering.

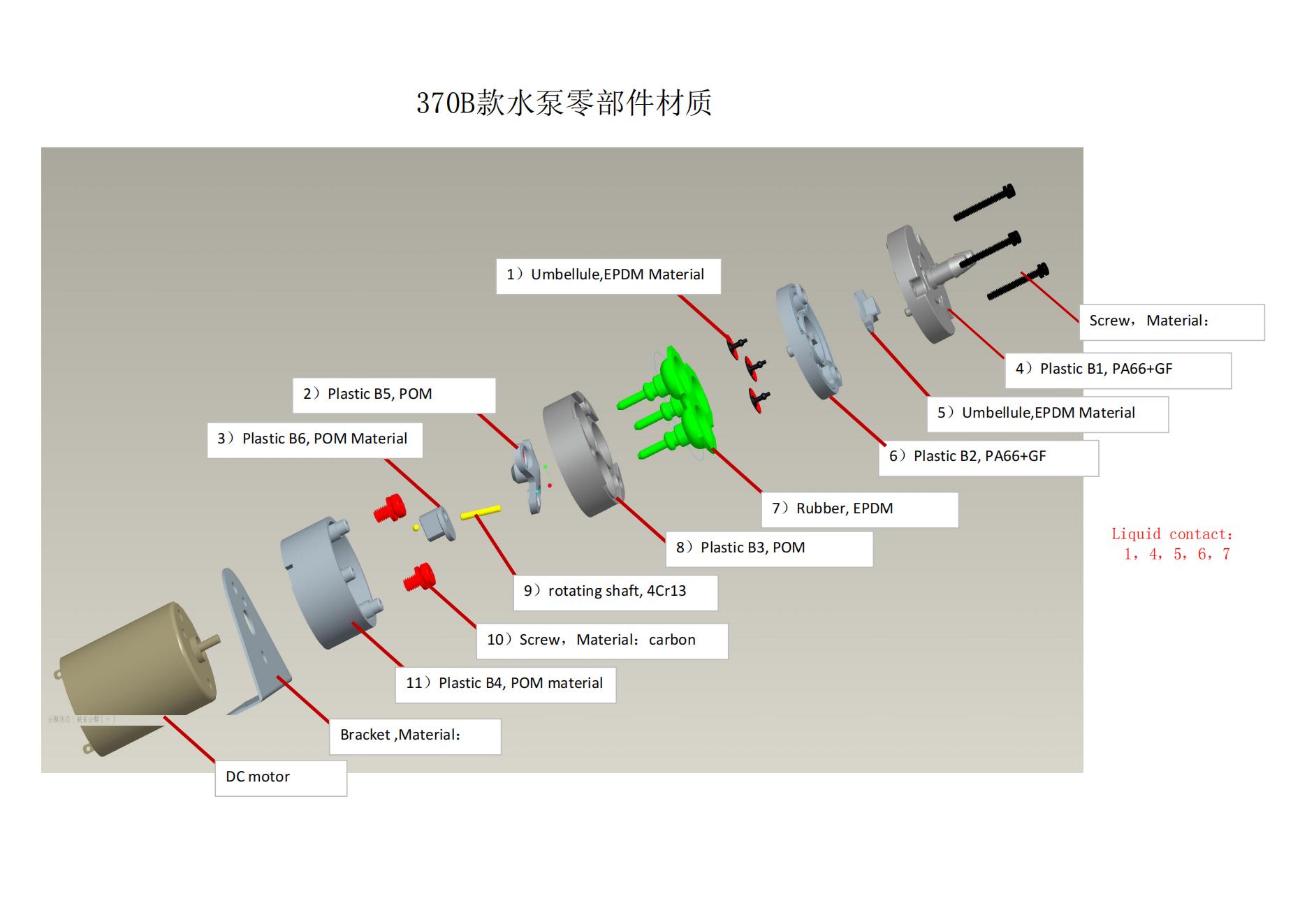

1. The Diaphragm: The Critical "Flex" Point

The diaphragm is the most stressed part of the pump. It must be flexible enough to move but tough enough to withstand millions of strokes.

What we've learned in the lab:

Material choice isn't just about chemistry; it’s about fatigue life.

-

EPDM: Great for general air and water. It’s cost-effective and resilient.

-

PTFE (Teflon): The "gold standard" for chemical resistance. However, it’s stiffer. If your design uses PTFE, your motor needs higher torque to overcome that stiffness.

-

Viton: Best for high-temperature or oily environments where EPDM would swell and fail.

Pro Tip: We recommend a "multi-layer" diaphragm approach for high-pressure applications to prevent premature tearing at the edges.

2. The Motor and Drive System: The Powerhouse

A pump is only as good as the motor driving it. In micro diaphragm pumps, we typically use Brushless DC (BLDC) motors for one reason: Longevity.

-

Brushless Motors: Essential for 24/7 industrial applications. They offer better heat dissipation and zero brush wear.

-

The Eccentric Wheel: This converts rotary motion into linear "pull and push." A common mistake is using a plastic eccentric in high-load scenarios. We use precision-machined metal eccentrics to ensure the stroke remains consistent over the pump's life.

3. The Valve System: Preventing Backflow

One-way valves (check valves) control the direction of flow. If these don't seal perfectly, your pump loses "head" (pressure) and efficiency.

-

Umbrella Valves vs. Flapper Valves: For high-speed cycling, we prefer umbrella valves because they offer a more symmetrical seal and react faster to pressure changes.

-

The "Debris" Problem: Most valve failures aren't due to wear, but tiny particles getting stuck. We always suggest adding a 50-micron filter at the inlet to protect the valve seats.

4. Engineering for Efficiency: Reducing "Dead Volume"

"Dead volume" is the air left in the chamber after a full stroke. If this volume is too large, the pump will struggle to prime itself (self-priming).

How we optimize this:

By matching the shape of the piston head exactly to the curve of the pump chamber, we minimize leftover space. This results in faster suction and higher vacuum levels.

Comparison: Choosing Your Diaphragm Material

| Material | Best For | Pros | Cons |

| EPDM | General Air/Water | Cheap, Long Life | Poor Oil Resistance |

| PTFE | Harsh Chemicals | Highly Inert | Stiff, Requires More Power |

| Viton | High Temp/Acids | Resists Swelling | More Expensive |

Frequently Asked Questions (FAQ)

How long should a diaphragm pump last?

In a controlled environment with a brushless motor, a high-quality pump should exceed 10,000 hours of continuous operation. However, diaphragm life is shorter if pumping corrosive fluids.

Why is my pump losing pressure?

Check for two things: First, inspect the valves for debris. Second, check the diaphragm for "micro-cracking"—a sign of material fatigue.

Can these pumps run dry?

Yes. One of the biggest advantages of diaphragm pump design is their ability to run dry indefinitely without damage, unlike centrifugal pumps.

Looking for a custom pump solution?

Our engineering team can help you select the right materials and motor specs for your specific project.

[Would you like us to provide a technical CAD drawing or a sample for your prototype?]

you like also all

Read More News

Post time: Feb-18-2025