High-Precision 12V Food-Safe Water Pump: FDA-Compliant Solutions for Premium Coffee Machines | Pinmotor

Customized Service

To provide customers with quality products and satisfactory service

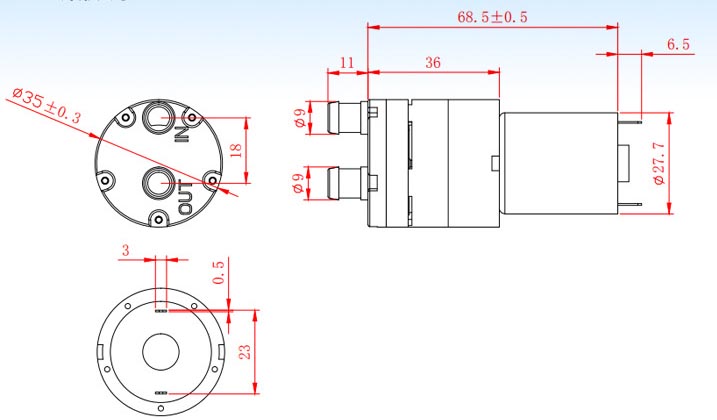

PYSP365-XA

Small Water Pump

How can I effectively prevent calcification and scale buildup when using this pump in hard water environments?

A (Lead Engineer's Advice): In hard water areas, calcium and magnesium ions can crystallize on the internal diaphragm and valves, leading to reduced flow or motor strain. To prevent this, we recommend a two-tier strategy:

Pre-filtration: Install a 100-mesh stainless steel filter at the inlet to capture initial physical sediment.

Decalcification Cycle: For coffee machine applications, perform a maintenance flush every 3–6 months using a food-grade citric acid solution. This dissolves early-stage limescale before it hardens, maintaining the flexibility of the EPDM diaphragm and extending the pump's service life by approximately 30%.

Specification Engineering Drawing

Application

| Target Industry | Core Challenges | Engineering Solution | Key Compliance |

|---|---|---|---|

| Coffee & Brewing (Espresso, Drip, Cold Brew) |

Flavor extraction & thermal stability at high temperatures. | Heat-resistant EPDM diaphragms maintain TDS integrity up to 80°C. | FDA Compliant |

| Water Purification (RO Systems, Ionizers) |

Stable pressure & prevention of chemical leaching. | BPA-free PPS housing with self-priming capability for flexible installation. | BPA-Free / Food Grade |

| Smart Vending (Soda, Juice, Milk Tea) |

Long maintenance cycles & low-noise operation. | Brushless motor design offering 1,000+ hours life and quiet performance (<45dB). | EMC / Low Noise |

| Medical & Lab (Analyzers, Sterilizers) |

Precise fluid dosing & chemical resistance. | Compact design with precise flow control for non-corrosive fluid transfer. | RoHS Compliant |

dishwasher

Electric decanter

Foam hand sanitizer

Water dispenser

Vacuum packing machine

Tea table

Images for micro gear pump---100% live-action shooting, Quality Guarantee

Types of Micro Pump Products

Best Micro Water Pump Manufacturer and Exporter In China

We can provide the best price and technical support for commercial projects.

Q1: What food-grade certifications does this 12V water pump carry for coffee applications?

A: Our pumps are manufactured using FDA-certified EPDM diaphragms and food-grade PPS housing. The entire liquid path is BPA-free and RoHS compliant. This ensures that even at high temperatures (up to 80°C/176°F), there is no chemical migration, maintaining the sensory integrity and safety of the coffee.

Q2: How can I prevent calcification (limescale) in hard water environments?

A: Calcification is the leading cause of pump failure. We recommend a two-step protection: 1. Install a 100-mesh pre-filter at the inlet. 2. Perform a monthly descale cycle using a 10% citric acid solution. This prevents the diaphragm from hardening and maintains a consistent flow rate over the pump’s 1,000+ hour lifespan.

Q3: Can this pump handle the high-temperature requirements of commercial espresso machines?

A: This model is optimized for continuous thermal stability. While the motor remains cool, the head assembly can withstand fluid temperatures up to 100°C (boiling) for short bursts and 80°C for continuous operation. It is ideal for both pre-heating and brewing cycles in professional coffee equipment.

Q4: Is the noise level low enough for a premium home coffee machine environment?

A: Yes. By using brushless motor technology and dampening mounts, the noise level is controlled under 45dB at a 50cm distance. This is quieter than a typical conversational whisper, ensuring a premium, quiet user experience for high-end household appliances.

Q5: What is the correct way to replace or upgrade the connectors to prevent leaks?

A: Always use food-grade PTFE tape on threads and ensure the O-ring is seated flush. For quick-connect fittings, ensure the tubing is cut square (90 degrees). We recommend PE or Silicone tubing with an inner diameter of 6mm to match the pump’s optimal intake pressure.