In environmental monitoring, industrial safety, and laboratory analysis, micro air pumps are crucial components in gas sampling systems. When analyzing corrosive gases, the choice of pump materials directly affects the accuracy of the analysis results and the service life of the equipment. Selecting the wrong material can compromise data quality and even lead to mini dc air pump failure.

This article provides a clear and practical reference for material selection in a straightforward manner.

Core Principle: Focus Only on Components in Contact with Gas

In micro pumps, only the components that directly contact the gas require consideration for corrosion resistance. These are typically referred to as "wet end" components and mainly include:

1、Pump Head/Cover: Provides structural support and has the largest contact area with the gas.

2、Diaphragm: Responsible for gas transfer, requiring good flexibility and fatigue resistance.

3、Valve Plates/Valves: Control the direction of gas flow, requiring quick response and good sealing.

Key Materials: "Wet End" Components — Choice Between Plastics and Elastomers

The "wet end" components mainly consist of materials such as high-performance plastics (used for pump heads) and high-performance elastomers (used for diaphragms and valves). Below, we will understand the characteristics of these materials with a focus on the "wet end" components.

Pump Head Materials: Balancing Strength and Corrosion Resistance

| Material Name | Abbreviation | Key Characteristics and Applications | Suitable Gas Types |

| Polyphenylene Sulfide | PPS | Good overall performance. High mechanical strength, good heat resistance, and broad tolerance to acids, alkalis, and solvents. Commonly used in most flue gas analysis (SO₂, NOx). | Weak acids, weak alkalis, common solvents |

| Polyvinylidene Fluoride | PVDF | Suitable for strong oxidizers. Excellent resistance to strong oxidizing gases like Cl₂, O₃ , and strong acids. | Strong oxidizers, strong acids |

| Polytetrafluoroethylene | PTFE | Chemically inert. Virtually unreactive with any chemicals. Suitable for environments demanding the highest purity or with complex, harsh gas compositions. | Almost all chemicals |

Practical Advice: If the gas contains high concentrations of chlorine or ozone, it is recommended to choose a PVDF or PTFE pump head, avoiding PPS.

Diaphragm/Valve Materials: Balancing Elasticity and Stability

Diaphragms and valves need to be elastic while also being corrosion-resistant.

| Material Name | Abbreviation | Key Characteristics and Applications | Cost and Applicability |

| Polyphenylene Sulfide | EPDM | Lower cost. Good resistance to acids, alkalis, and water vapor. However, it has poor resistance to oils and most organic solvents (VOCs). | Low cost, suitable for conventional corrosive gases without VOCs. |

| Polyvinylidene Fluoride | FKM | Versatile. Good resistance to organic solvents, hydrocarbons (VOCs), and strong acids. A commonly used elastomer in industrial analysis. | Moderate cost, reliable performance, suitable for most industrial environments. |

| Polytetrafluoroethylene | FFKM | Best corrosion resistance. Chemical performance close to PTFE while maintaining rubber elasticity. Resistant to almost all chemical media. | Very high cost, used only for extremely harsh, mission-critical applications where interruption is not an option. |

Practical Advice: If the gas contains any hydrocarbons or organic solvents (VOCs), do not choose EPDM. Instead, select FKM or FFKM.

Three-Step Decision Process: How to Choose Correctly?

Material selection is not about choosing the most expensive option, but about matching the actual situation.

Step 1: Identify Gas Composition and Concentration

This is the most critical basis for material selection. You need to know the most corrosive component in the gas to be measured and its maximum concentration.

- Example One: Conventional flue gas (low concentration SO₂、NOx): PPS pump head + FKM diaphragm/valves.

- Example Two: Chlorine analysis in chlor-alkali plants (high concentration Cl₂): PVDF pump head + FFKM diaphragm/valves.

Step 2: Consider the Impact of Temperature

Temperature accelerates corrosion. A material resistant at room temperature may fail quickly at elevated temperatures. Always consult material compatibility charts based on the actual operating temperature.

Step 3: Balance Cost and Risk

- Low Risk / Routine Applications: Choose the PPS/FKM combination for the best cost-performance ratio.

- High Risk / Critical Applications: Choose the PVDF/PTFE/FFKM combination. Although the initial investment is higher, it offers longer service life and higher analysis reliability, proving more economical in the long run.

Reminder: In corrosive gas analysis, material compatibility is paramount. Material failure not only results in a damaged small air pump but potentially also in a batch of erroneous analysis data.

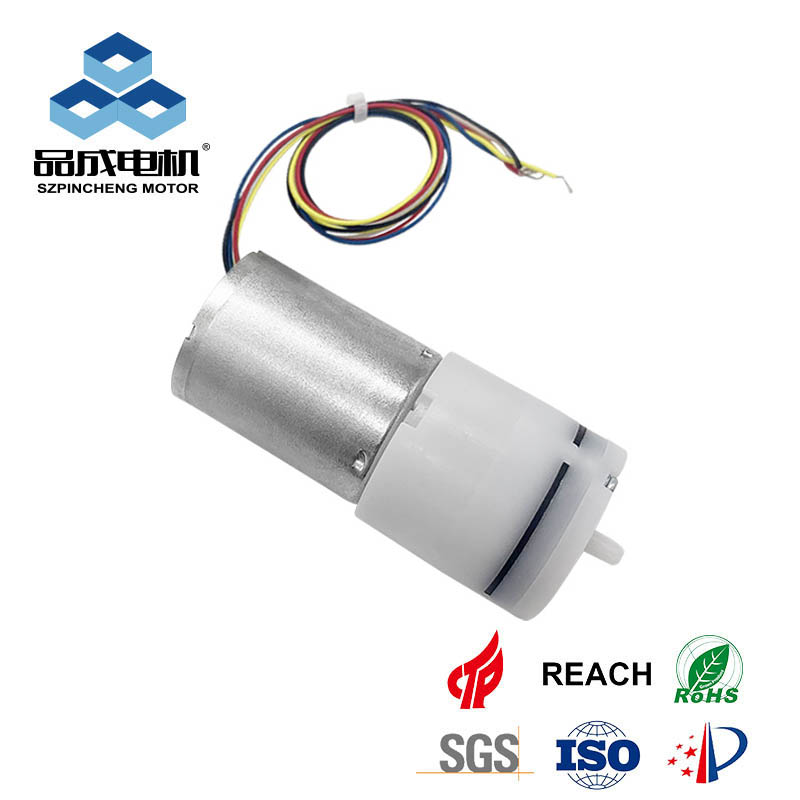

Recommend products

Post time: Dec-11-2025