Compare, select, buy your pump

High Torque 12V DC Motor for Medical & Industrial Use

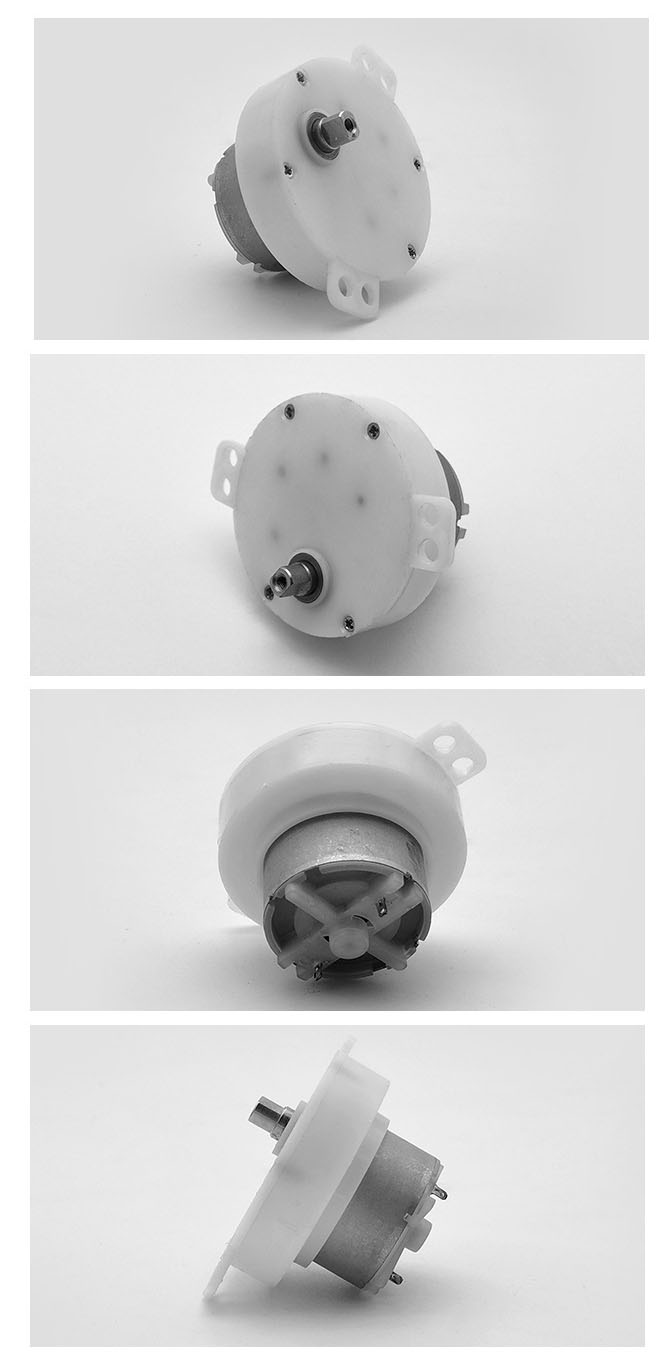

PC-JS50 Micro Gear Motor

The PC-JS50 is a high-torque Micro Annular Gear Pump Motor designed for precision fluid control and actuation. Operating at 12V/24V with ultra-low noise (<45dB), its internal gear structure minimizes backlash for medical dosing, smart electronic locks, and robotics. ISO9001 certified and fully customizable (Shaft/RPM) for OEM integration.

Technical Specifications

| Model | Voltage | No-Load | At Maximum Efficiency | Stall | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Range (V) |

Nominal (V) |

Speed (r/min) |

Current (A) |

Speed (r/min) |

Current (A) |

Torque (mN.m) |

Output (W) |

Torque (mN.m) |

Current (A) |

|

| PC-JS50CF-11590 | 9.0-13.0 | 12.0 | 10 | 0.057 | 7.7 | 0.17 | 110.5 | 0.89 | 480.0 | 0.59 |

| PC-JS50CF-071380 | 20.0-25.0 | 24.0 | 60 | 0.020 | 45.6 | 0.06 | 165.2 | 0.79 | 688.2 | 0.20 |

* Note: Data measured at room temperature. Custom performance parameters available upon request.

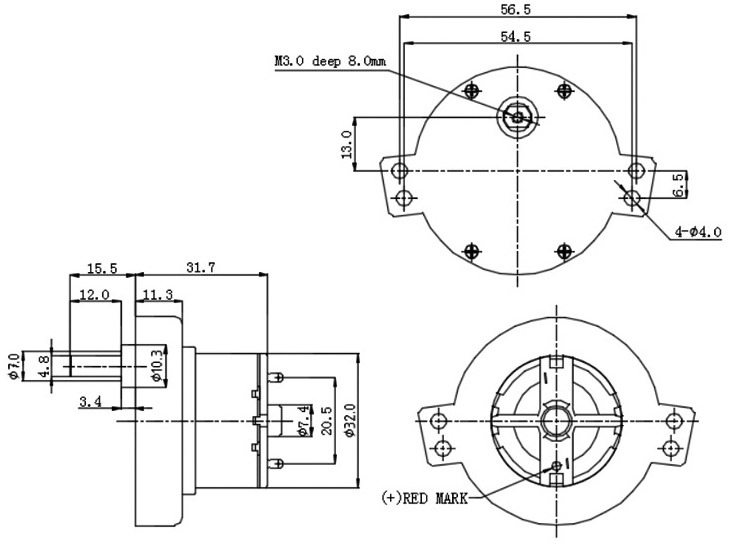

Specification Engineering Drawing

Product Applications

| Application | Specific Usage | Key Advantage (Why PC-JS50?) |

|---|---|---|

| Display Stand | Rotating Turntables for Jewelry/Products | High Torque/Low Speed: The 1:718 reduction ratio allows smooth, slow rotation (e.g., 10 RPM) capable of carrying heavier display items without stalling. |

| Lamp / Lighting | Rotating Stage Lights or Decorative Lamps | Compact Integration: The small footprint (approx 50mm) fits easily into lamp bases. Low power consumption (0.01-2.0W) ensures energy efficiency. |

| Actuator | Smart Home Automation & Locking Mechanisms | Precision Control: The built-in precision gear system translates high-speed motor input into controlled, powerful linear or rotary movement. |

| Fan | Fan Head Oscillation (Swing Mechanism) | Durability: Engineered to handle continuous side-to-side movement. The gear reduction provides the necessary torque to move the fan head smoothly. |

| Toy | RC Cars, Robots, or Moving Figures | Safety Voltage: Operates safely at 12V/24V. The plastic housing option offers a lightweight solution ideal for portable or battery-operated toys. |

| Craft Gift | Music Boxes & Kinetic Ornaments | Silent & Stable: Optimized for quiet operation to maintain the aesthetic quality of premium gifts. Customizable shaft allows for various mounting options. |

Tea table

Vacuum packing machine

Water dispenser

Foam hand sanitizer

Electric decanter

dishwasher

Manufacturing Quality & Compliance

At Pinmotor, every PC-JS50 unit undergoes rigorous end-of-line testing to guarantee zero-defect integration into your automated assembly lines. Our production facility operates under ISO9001 & IATF16949 quality management systems, ensuring this micro gear pump fully complies with global RoHS and REACH standards for medical and smart automation markets.

ISO 9001:2015 Certified

Our quality management system ensures consistent product output, from raw material inspection to final functional testing of every dc motor.

IATF 16949 Compliant

We leverage automotive-grade process discipline to guarantee ultra-low defect rates and long-term reliability in consumer electronic applications.

RoHS & REACH Fully Compliant

All materials used in the JS DC GEAR MOTOR series—including the motor brushes, diaphragm, and housing—are free from hazardous substances, ensuring your end-product is ready for the EU and North American markets.

Technical Note: Full documentation, including material safety data sheets (MSDS) and compliance certificates, is available upon request for your engineering audit.

We supply more than just product, we engineer solutions optimised to suit your application requirements.

Q1: Can I customize the shaft specifications or voltage for the PC-JS50?

Yes. As an original manufacturer (OEM/ODM), PinMotor can customize the PC-JS50 to fit your specific assembly. We can modify the voltage range (3V – 24V), the shaft length and shape (D-cut, Round, or Threaded), and adjust the gear ratio to achieve your target torque and speed. Please attach your technical drawing when inquiring.

Q2: How does the annular gear design differ from standard spur gears?

The annular (internal) gear design used in the PC-JS50 offers superior torque distribution compared to standard external spur gears. This results in lower backlash, reduced vibration, and significantly quieter operation (<45dB), making it ideal for noise-sensitive environments like medical devices and smart home locks.

Q3: What is the expected service life of this micro gear motor?

Under rated load conditions at 12V, the PC-JS50 is tested to achieve a continuous service life exceeding 500 hours. However, lifespan varies based on load, duty cycle, and operating environment. For applications requiring extreme longevity (2000+ hours), we can upgrade the internal brushes to carbon brushes or brushless structures upon request.

Q4: Is the PC-JS50 suitable for continuous 24/7 operation?

This model is primarily designed for intermittent duty cycles (e.g., locking/unlocking, dispensing fluids). Continuous running for extended periods may generate heat that affects motor efficiency. If your application requires continuous 24-hour operation, please contact our engineering team so we can recommend a brushless solution with better thermal management.

Q5: How can I control the speed of this DC gear motor?

Since the PC-JS50 is a brushed DC motor, its speed is directly proportional to the applied voltage. For precise speed control, we recommend using a PWM (Pulse Width Modulation) controller. This allows you to adjust the RPM effectively without significantly sacrificing torque output at lower speeds.