310 Micro DC Foam Pump (3V/6V) with Bubbler | Automatic Soap Dispenser Pump | Pincheng

Customized Service

To provide customers with quality products and satisfactory service

PYFP310-XE

Silent Operation, Durability, and High Efficiency

The core diaphragm and valves of the pump are made from industrial-grade EPDM (Ethylene Propylene Diene Monomer) material. This means the 310XE can safely and stably pump chemical agents containing alcohol (up to 95% concentration), acids, or alkalis. This effectively solves the common issues of material aging and leakage found in traditional pumps, significantly extending the product's service life..

Product Information

| Rated Current | DC 3V | DC 3.7V | DC 4.5V | DC 6V |

| Rated Current | ≤750mA | ≤600mA | ≤500mA | ≤350mA |

| Power | 2.2w | 2.2w | 2.2w | 2.2w |

| Air Tap O.D. | φ 4.6mm | |||

| Water Flow | 30-100 mLPM | |||

| Water Flow | 1.5-3.0 LPM | |||

| Noise Level | ≤65db (30cm away) | |||

| Life Test | ≥10,000 Times (ON:2seconds,OFF:2seconds) | |||

| Pump Head | ≥0.5m | |||

| Suction Head | ≥0.5m | |||

| Weight | 40g | |||

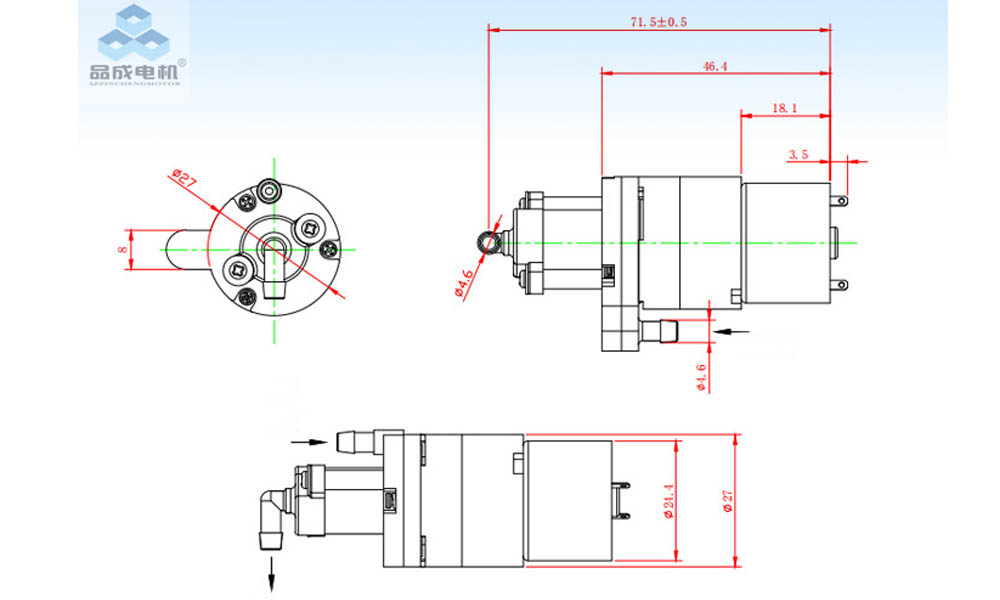

Specification Engineering Drawing

Application

Our optimized motor and specialized damping structure allow the 310XB to operate with an ultra-low noise level of $\le 65\text{dB}$ (measured at 30cm). This design specifically targets noise-sensitive products, making the pump ideal for premium automatic soap dispensers, medical devices, and quiet home appliances.

Tea table

Vacuum packing machine

Water dispenser

Foam hand sanitizer

Electric decanter

dishwasher

Images for micro foam pump---100% live-action shooting, Quality Guarantee

Product Photograph Real Shot

How does a foamer pump work?

Foamers pump is a type of positive displacement pump used to generate a foam. It works by introducing air into a liquid, so that bubbles are generated and dispersed. The air is usually introduced through an injector, and the liquid passes through an impeller, which creates turbulence and helps create more foam. As the liquid exits the impeller, the bubbles form a foamy product that can be discharged from the pump.

How do you use a foam pump?

To use a foam pump, start by connecting the air hose to an air compressor and making sure it is securely attached. Then, open up the valve on the air compressor to start pumping air. Next, connect the liquid line to the pump’s inlet and make sure it is fully sealed. Now, turn on the pump and allow the liquid and air to mix together. Once the foam has been created, you can adjust the foam’s thickness and quality by adjusting the amount of air being pumped in. Lastly, disconnect the hose from the air compressor and discharge the foam from the pump.

how to take apart a foam soap dispenser pump

To take apart a foam soap dispenser pump, you need to turn it upside down and unscrew the top lid. Then, you should be able to separate the pump from the container. You can then remove the inner components and replace them if necessary.

how to fix foam pump

If your foam pump have any quality problem, please contact us. we will help that.

how long can a foam pump run dry without damage?

Generally speaking, the reasons why the foam pump will become difficult to pump out are as follows: 1. The water quality is too hard; 2. The temperature is too high; 3. The pressure is not enough; 4. The liquid contains very little anticoagulant; Air pressure is too high.

why does a soap foam pumpget hard to pump

Generally speaking, when the soap is thicker than the soap pump can handle, the soap pump can become difficult to draw. In this case, it may harden and eventually it may stick or stop functioning. Also, air bubbles in the soap solution may reduce the pump’s treatment effectiveness. Therefore, it is generally not recommended to use too much bubbles and foam to lather soap.