Compare, select, buy your pump

Low speed high torque DC gear motor 12V

Customized Service

To provide customers with quality products and satisfactory service

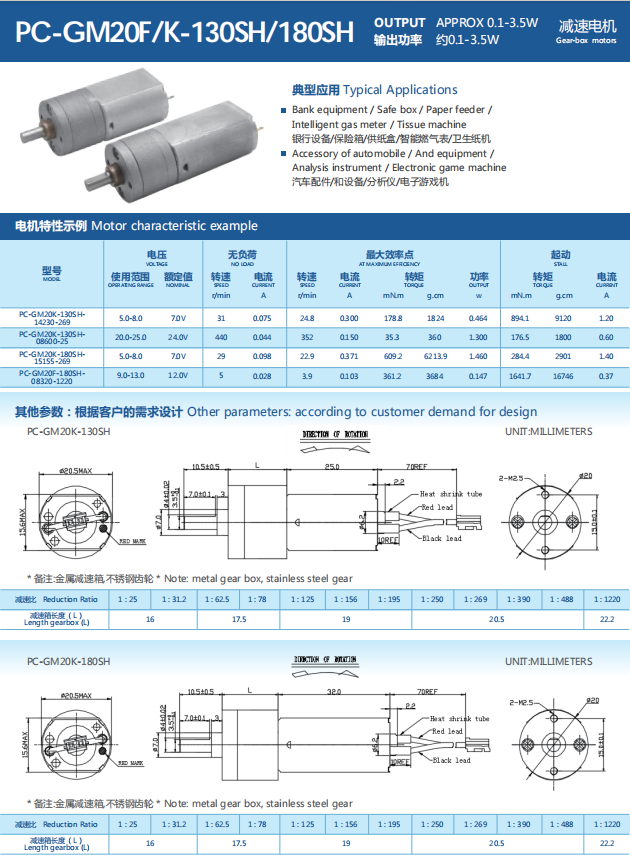

GM20F/K-130SH/180SH micro DC gear motor

This High efficiency 24V micro motor is perfect for bank equipment, safe boxes, and paper feeders. As a durable DC Reduction Motor, it is also widely used in intelligent gas meters, medical analysis instruments, and electronic hair curlers.

Product Information

| Model | Voltage | No Load | At Maximum Efficiency | Stall | ||||||||

| Operating Tange | Nominal | Speed (r/min) | Current (A) | Speed (r/min) | Current (A) | Torque | Output (W) | Torque | Current (A) | |||

| GM20K-130SH-14230-269 | 5.0-8.0 | 7.0V | 31 | 0.075 | 24.8 | 0.300 | 178.8 | 1824 | 0.464 | 894.1 | 9120 | 1.20 |

| GM20K-130SH-08600-25 | 20.0-25.0 | 24.0V | 440 | 0.037 | 352 | 0.150 | 35.3 | 360 | 1.300 | 176.5 | 1800 | 0.60 |

| GM20K-180SH-15155-269 | 5.0-8.0 | 7.0V | 29 | 0.098 | 22.9 | 0.371 | 0.371 | 609.2 | 1.460 | 284.4 | 2901 | 1.40 |

| GM20F-180SH-08320-1220 | 9.0-13.0 | 12.0V | 5 | 0.028 | 3.9 | 0.103 | 361.2 | 3684 | 0.147 | 1641.7 | 16746 | 0.37 |

Specification Engineering Drawing

Application

Micro dc motor is suitable for a variety of application scenarios

Typical applications:medical treatment, beauty care, massage, adult products, medical equipment;

Tea table

Vacuum packing machine

Water dispenser

Foam hand sanitizer

Electric decanter

dishwasher

Images for micro gear pump---100% live-action shooting, Quality Guarantee

We supply more than just product, we engineer solutions optimised to suit your application requirements.

Q1: Why does this motor use stainless steel gears instead of plastic ones?

A: This series is engineered for heavy-duty applications. Stainless steel gears offer significantly higher hardness and wear resistance compared to plastic or powder metallurgy gears. They can withstand much higher stall torque and impact loads without stripping teeth, ensuring long-term reliability in high-frequency start-stop cycles (like tape cutting or banking equipment).

Q2: How do I choose between the 130SH and 180SH motor series?

A: It depends on your power and space requirements:

-

130SH Series: Ideal for compact spaces where moderate power (0.1W – 1.3W) is sufficient. It is more energy-efficient for lighter tasks like paper feeding.

-

180SH Series: Choose this if you need higher output power (up to 1.46W) and superior torque. The 180 motor is longer (32mm vs 25mm) but provides the extra “punch” needed for heavy-duty cutting or lifting.

Q3: What should I consider regarding the “Stall Current” when designing my circuit?

A: The Stall Current (e.g.,1.20A for the 130SH-14230) is the maximum current drawn when the motor is forced to a stop. Your power supply and motor driver (e.g., L298N, TB6612FNG) must be rated to handle this peak current. If your driver can only handle 0.5A but the motor stalls at 1.2A, the driver will likely overheat or burn out.