Compare, select, buy your pump

Diaphragm air pump 3V small electric booster air pump | PINCHENG

Customized Service

To provide customers with quality products and satisfactory service

PYP310-XA

High-Durability Micro Diaphragm Technology

The Pincheng Micro Diaphragm Series is engineered for versatile fluid management, delivering consistent flow rates across air, water vapor, and liquid media. Its compact footprint does not compromise performance, making it an ideal choice for space-constrained medical and industrial integrations.

Advanced Valve Architecture & Longevity

The superior service life of this miniature vacuum pump is driven by two core design principles:

-

Optimized Laminar Flow: The valve flow path is precision-molded to be ultra-smooth, minimizing internal turbulence and ensuring a stable, constant displacement.

-

Hard-Composite Valve Materials: By utilizing high-durometer, abrasion-resistant internal components, the pump maintains structural integrity under high-frequency oscillation. This rugged construction allows the unit to consistently pass rigorous industrial certification tests and long-term reliability trials.

Product Information

|

PYP310-XA Diaphragm air pump |

||||

| *Other Parameters: according to customer demand for design | ||||

| Rate Voltage | DC 3V | DC 6V | DC 9V | DC 12V |

| Rate Current | ≤800mA | ≤400mA | ≤260mA | ≤200mA |

| Power | 2.4w | 2.4w | 2.4w | 2.4w |

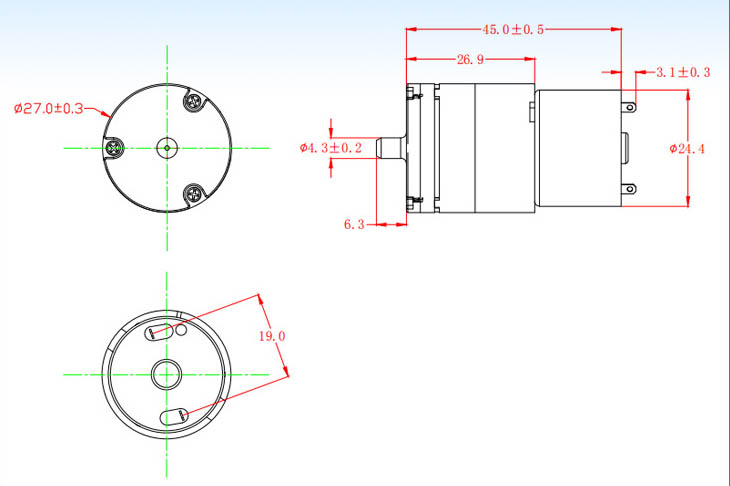

| Air Tap .O.D | φ 4.3mm | |||

| Air Flow | 0.5-3.0 LPM | |||

| Inflation Time | ≤10s (From 0 to 300 mmHg in a 500cc tank | |||

| Maximum Pressure | ≥60Kpa(450mmHg) | |||

| Noise Level | ≤60db (30cm away) | |||

| Life Test | ≥50,00 Times (ON 10 s;OFF 5s) | |||

| Weight | 36g | |||

| Leakage | <3mm Hg/min (From 300 mmHg in a 500cc tank | |||

Specification Engineering Drawing

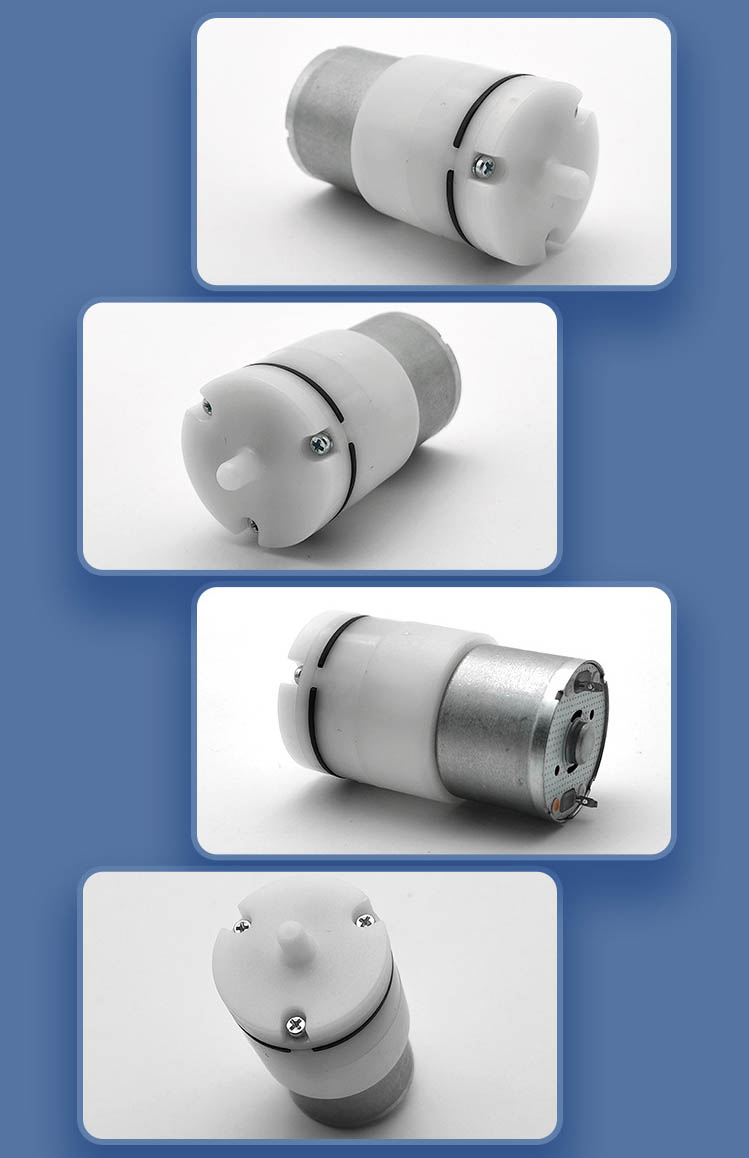

Images for micro gear pump---100% live-action shooting, Quality Guarantee

Application

The PYP130 3V micro pump is engineered for high-precision, low-power environments. Below is a technical breakdown of its deployment across key industrial and medical sectors.

| Industry Sector | Typical Application | Key Benefit of PCW030 | Technical Requirement |

| Medical Devices | Portable Blood Pressure Monitors | High-torque startup at $\le 1.5\text{V}$ | Stable inflation pressure $\ge 350\text{ mmHg}$ |

| Healthcare | Eye Massagers & Wearables | Ultra-low noise profile ($< 55 \text{ dB}$) | Compact footprint for ergonomic design |

| Beauty Tech | Blackhead Removers / Hydrafacial | Precise vacuum suction control | Abrasion-resistant EPDM diaphragm |

| Environment | Handheld Gas Detectors | Consistent laminar airflow | Chemical-resistant internal valve path |

| Aromatherapy | Smart Scent Diffusers | Reliable long-term duty cycle | Zero-leakage pneumatic seal |

| Automation | Microfluidic Gas Sampling | Fast priming & response time | PWM-compatible flow adjustment |

Tea table

Vacuum packing machine

Water dispenser

Foam hand sanitizer

Electric decanter

dishwasher

Manufacturing Quality & Compliance

PinMotor leverages high-precision automotive process disciplines to ensure our 3V micro pumps deliver industrial-grade reliability within consumer-scale footprints. By implementing rigorous quality frameworks, we provide a stable supply chain for high-volume medical and beauty device manufacturers.

ISO 9001:2015 Certified

We don't just source materials; we verify them. Every batch of EPDM rubber and high-carbon steel motor brushes undergoes durometer testing and composition analysis to ensure thermal stability and wear resistance under high-frequency oscillation.

IATF 16949 Compliant

We don't just build pumps; we engineer reliability into the design phase. Following APQP frameworks, we perform DFMEA (Design Failure Mode and Effects Analysis) on every 3V pump variant to identify and mitigate potential failure points—such as diaphragm fatigue or valve oxidation—before mass production begins.

RoHS & REACH Fully Compliant

The PYP310 Series is engineered for seamless integration into international markets. We proactively manage our supply chain to ensure every component—from the high-performance motor brushes to the EPDM diaphragm—meets the stringent environmental and safety standards of the European Union and North America.

Technical Note: Full documentation, including material safety data sheets (MSDS) and compliance certificates, is available upon request for your engineering audit.

We supply more than just product, we engineer solutions optimised to suit your application requirements.

Technical FAQ: 3V Micro Diaphragm Air Pump

What is the rated service life of the 3V micro air pump?

The Pincheng 3V micro pump is rated for a service life of ≥ 100,000 cycles under standard load conditions (10s on/5s off). Actual longevity depends on duty cycle and environmental factors; for continuous duty applications, we recommend consulting our engineers for MTBF data.

Can this 3V pump operate on a 3.7V Lithium-ion battery?

Yes. While optimized for 3V DC, the pump’s operating voltage range is 1.5V to 3.7V. Operating at 3.7V will increase airflow and pressure but may slightly elevate noise levels and thermal output during extended runs.

Is the PCW030 air pump compatible with medical-grade silence requirements?

Our 3V pump operates at < 55 dB when measured from a distance of 30cm. For ultra-quiet medical environments (bedside monitors), we suggest using localized sound-dampening foam or silicone vibration mounts to further reduce acoustic resonance within the device housing.

What materials are used in the diaphragm, and are they chemical resistant?

We utilize high-grade EPDM (Ethylene Propylene Diene Monomer) for the diaphragm and high-strength engineering plastics for the pump head. This combination offers excellent ozone resistance and durability, though it is primarily designed for air and non-corrosive gas media.

What are the standard port dimensions for tubing integration?

The pump features a standard barbed nozzle design. We recommend using medical-grade silicone tubing with an inner diameter (ID) of 2.0mm to 3.0mm to ensure a secure, leak-proof friction fit without the need for external clamps.

Does Pincheng Motor offer OEM/ODM customization for specific flow rates?

Yes. We can customize motor windings, valve materials, and port orientations to meet specific pressure or flow requirements. Small-batch samples are typically available for engineering validation within 5–7 business days.