High-Performance Micro Water Pump Solutions: An Engineering Selection Guide

By Jinxiu Wang, Senior R&D Engineer at Pinmotor Last Updated: January 2026 | Reviewed for Technical Accuracy by Pinmotor Lab Team

1. Beyond the Specs: Why Selection Experience Matters

Selecting a micro water pump isn't just about matching flow rate and voltage. In our 20+ years of manufacturing experience, we’ve seen how overlooked variables—like fluid viscosity, backpressure, and thermal duty cycles—can turn a prototype into a field failure.

Engineer’s Experience Note: > "We once assisted a client in the medical hemodialysis sector whose pumps were failing due to micro-bubbles. By switching to a custom-valved diaphragm design, we eliminated air-lock issues and increased system reliability by 300%."

2. Core Technical Parameters & Real-World "Pro-Tips"

A. Flow Rate & Pressure Management

Standard datasheets show "peak" performance, but real-world performance drops once filters and valves are added.

-

Pro-Tip: Always calculate the Total Dynamic Head (TDH). If you ignore the cracking pressure of a check valve, you risk driving the motor into a stall, leading to premature coil burnout.

B. Thermal Stability & Duty Cycle

Will your pump run for 30 seconds or 24 hours?

-

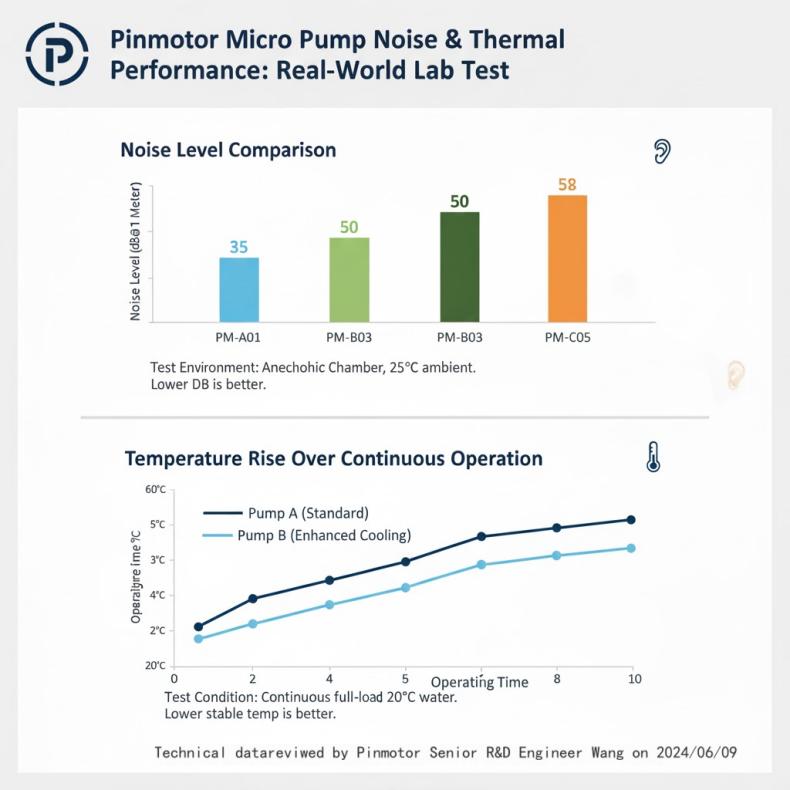

Pro-Tip: For continuous-run applications (e.g., server liquid cooling), we recommend our Brushless DC (BLDC) series with ceramic bearings. Our lab tests (see chart below) show a 15°C lower operating temperature compared to standard carbon-brush motors.

C. Noise & Vibration Decoupling

-

Pro-Tip: A "quiet" 35dB pump can become a 55dB nuisance if bolted directly to a rigid plastic chassis. Use silicone vibration dampers to decouple the pump from the frame—this is often more effective than choosing a more expensive silent model.

3. Performance Evidence: Real-World Lab Data

Figure 1: Comparative analysis of Pinmotor Series B vs. Market Standard in a controlled 10,000-hour endurance test.

4. Industry-Specific Solutions

We don't just sell pumps; we provide fluidic heartbeats for:

-

Medical & Lab Automation: High-precision dosing with chemically resistant PTFE membranes.

-

Commercial Appliances: Food-grade (NSF/FDA compliant) pumps for high-end coffee and beverage systems.

-

Automotive Cooling: 12V/24V BLDC pumps designed for extreme vibration and temperature fluctuations.

5. FAQ: Expert Solutions to Common Challenges

Q: Can these pumps handle acidic or alkaline fluids?

A: It depends on the seal material. In our experience, while EPDM is great for water, it will swell and seize if exposed to oils. For chemical dosing, we exclusively recommend Viton (FKM) or Perfluoroelastomer (FFKM) seals.

Q: How do I prevent "Water Hammer" from damaging the pump?

A: We suggest implementing a PWM soft-start via the controller. This ramps up the motor speed gradually, preventing the sudden pressure spikes that crack housings.

6. About the Author & Pinmotor Trust Signals

Jinxiu Wang is a lead engineer at Pinmotor, specializing in micro-fluidic dynamics.

-

In-house Testing: Every batch undergoes 100% pressure and leak testing before shipment.

-

Global Compliance: All solutions meet RoHS, CE, and REACH standards.

Recommend products

Read More News

Post time: Jan-07-2025