In the beverage industry, the 370 micro diaphragm pump is a favorite for espresso machines and milk frothers. However, "370" only refers to the motor size. For food safety, the true answer lies in the wetted materials and FDA/LFGB certifications.

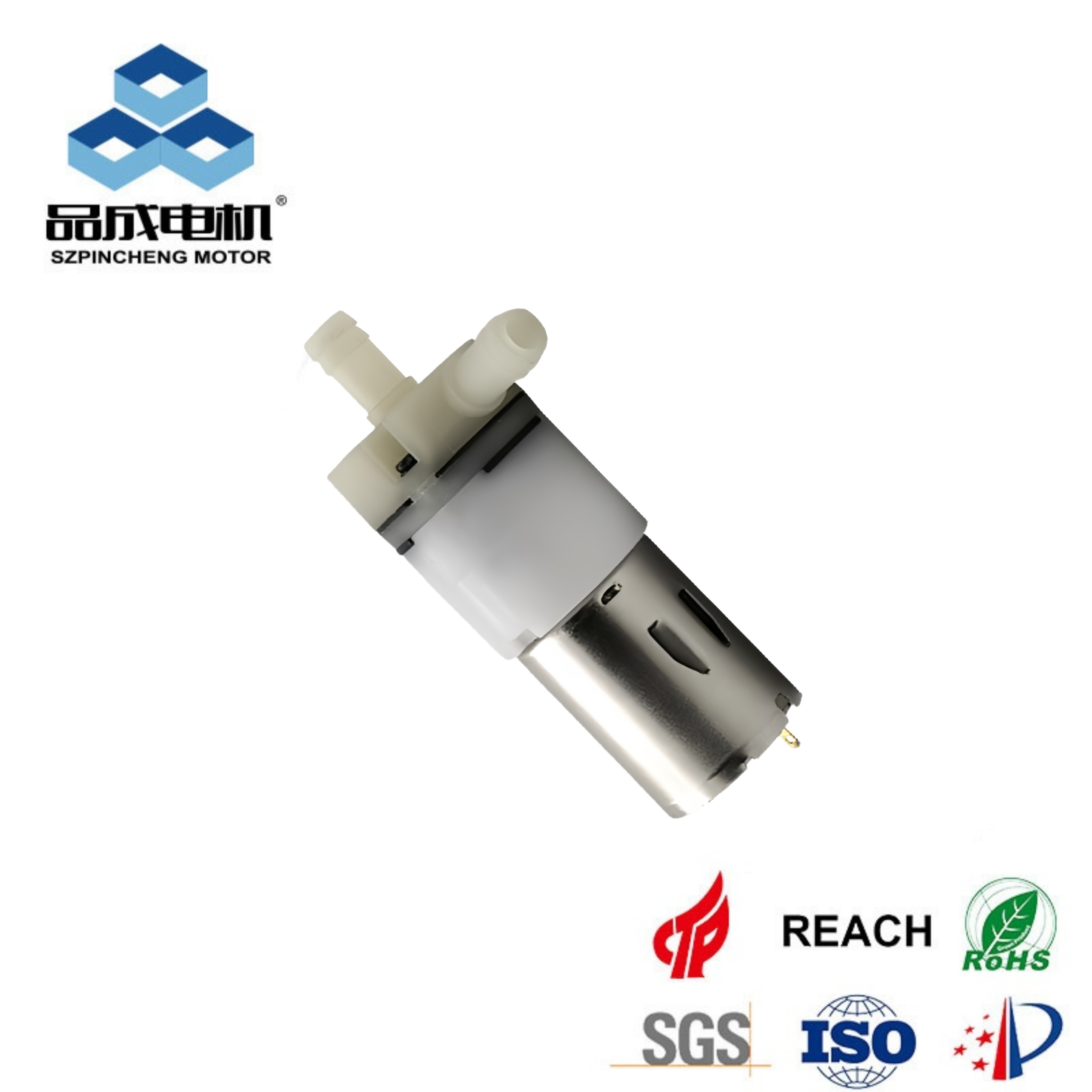

This guide explains how PinMotor engineers 370 pumps to meet international food-grade standards for coffee and water dispensers.

Industrial vs. Food-Grade: What’s the Difference?

Don't compromise safety for cost. Here is how to distinguish them:

| Component | Industrial Grade (Standard) |

Food-Grade (PinMotor Selection)

|

| Pump Head | Standard ABS / Nylon |

Food-Grade PP / PPS

|

| Diaphragm | Nitrile Rubber (NBR) |

Certified Silicone / EPDM

|

| Compliance | RoHS / REACH |

FDA / LFGB / BPA-Free

|

| Heat Limit | < 60Ā°C |

Up to 95Ā°C (For Hot Coffee)

|

| Odor/Taste | Potential Plastic Taste |

Organoleptically Neutral

|

I. Material Science: The "Wetted Path"

1. BPA-Free Housing (PP or PPS)

Standard industrial pumps may leach chemicals when exposed to heat. PinMotor uses High-Purity Polypropylene (PP) or Polyphenylene Sulfide (PPS). These materials are chemically inert and will not leach phenols or VOCs into your beverage.

2. Certified Elastomers (Silicone & EPDM)

The diaphragm is the most critical moving part.

-

EPDM: Ideal for hot water and coffee acids.

-

Food-Grade Silicone: Best for milk and applications requiring extreme flexibility.

-

PinMotor Advantage: All our food-grade elastomers undergo SGS/TUV extraction tests to ensure they meet the strictest FDA 21 CFR standards.

II. Challenges of Pumping Hot Coffee

High-Temperature Stability

Coffee brewing requires water at 85°C - 95°C. At these temperatures, standard plastics can soften. A genuine food-grade 370 pump must be designed with thermal-resistant polymers to prevent leaks and maintain PSI under heat stress.

Acidity & Essential Oils

Coffee contains natural oils that can cause industrial-grade rubber to swell or become sticky. Using certified EPDM ensures the pump maintains its flow rate even after thousands of brewing cycles.

III. How to Verify Food-Grade Compliance

-

Request the "Declaration of Compliance": A reputable supplier like PinMotor provides specific material test reports for the pump head, diaphragm, and O-rings.

-

Verify the Testing Lab: Ensure certifications are from globally recognized bodies like SGS, TUV, or Intertek.

-

Clean-Room Assembly: Look for pumps assembled in dust-free environments to prevent the introduction of industrial oils during manufacturing.

FAQ: Food-Grade 370 Pump Sourcing

Q: Can I use a standard 370 pump for a drinking water fountain?

A: No. Industrial pumps use NBR diaphragms which can impart a rubbery taste and potentially leach hazardous substances into the water. Always specify "Food-Grade" during procurement.

Q: Is the 370 pump dishwasher safe?

A: No. While the pump head is food-grade, the motor is not waterproof (unless specified as IP68). Only the internal fluid path should be cleaned using food-safe descaling agents.

Q: Does food-grade material reduce the pump's lifespan?

A: Actually, it often increases it. High-grade materials like PPS and EPDM have superior resistance to heat and chemicals compared to budget industrial plastics.

Conclusion: Partner with PinMotor for Safety

At PinMotor, we understand that your brand's reputation depends on the safety of your product. Our Food-Grade 370 Series is built to exceed FDA and LFGB requirements, ensuring your coffee machines deliver nothing but pure flavor and reliable performance.

Looking for LFGB-certified samples for your project?

Recommend products

Post time: Jan-16-2026