There is an art to the perfect latte or cappuccino, and at the heart of that art lies in the silky, silky microbubbles whipped up by a skilled foam maker.Barista skills is undeniable, but fundamentally depends on the foam stability and quality coffee machine precision of the internal components.Specifically, the micro pumps play a vital role in optimizing the pressure and air to milk ratio, which is often the key to making good foam.This article will explore the magical technology behind the milk foam, we will reveal the small equipment, including micro diaphragm pump, is the secret of how to build perfect become stable micro bubbles.

The science of microbubbles

Microbubbles are not simply bubbles;It is a stable emulsion composed of tiny uniform bubbles suspended in milk. Two elements are required to achieve microfoam: heating (steam) and precisely controlled air pressure.

Effect of air pressure

Traditional Italian coffee machines use steam rods, relying on high-pressure steam to heat milk simultaneously and inject air. However, modern automatic milk foam systems usually use dedicated air pumps to inject an appropriate amount of air into milk or steam pipelines. At this point, the micro diaphragm air pump comes in handy.

Diaphragm type air pump advantages

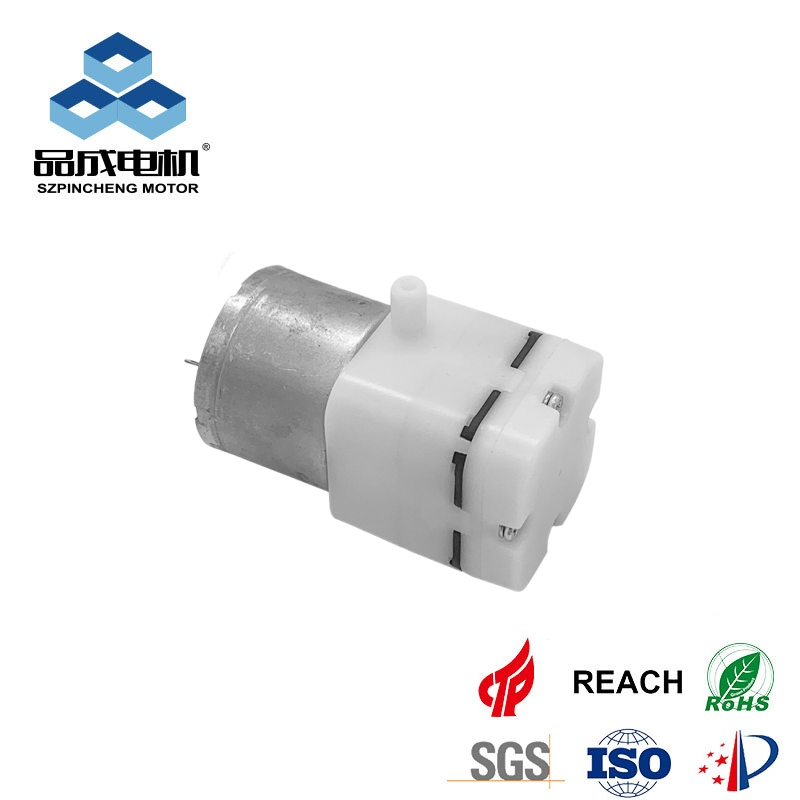

Diaphragm air pumps are highly suitable for this application as they are oil-free, ensuring that milk is not contaminated in any way.In addition, the high quality 12V DC micro diaphragm pump also has the following advantages:

1. Precise flow control: The air pump can be electronically controlled to deliver a precise amount of air to produce the required bubble size.

2. High reliability: The design of the mini diaphragm pump is simple and robust, which ensures long-term stable operation in high cycle environments such as commercial coffee machines.

Dual pump system: air pump and vacuum pump

In advanced automated milk foaming systems, two types of micro-pumps are typically used to work together to control the flow of air and milk:

1. Air pump (positive pressure) Mini diaphragm air pumps or small air diaphragm pumps are used to inject compressed air into milk or steam pipelines.Air is essential to produce the initial bubble.The ability of the pump to maintain a steady, non-pulsating airflow is key to ensuring a uniform bubble size, which determines the quality of the microfoam.The 12V mini diaphragm pump is a common choice because of its balanced power and small size, suitable for integration into desktop equipment.

2. Vacuum pump (negative pressure Micro diaphragm vacuum pumps are usually used to pump milk out of the container and into the bubble chamber.This ensures a steady and controllable flow of milk, which is no less important than air pressure.By controlling the vacuum, the pump can accurately measure the amount of milk, prevent waste and ensure consistency of the formula.

Optimize the pressure of microbubbles

The quality of the microfoam is proportional to the stability and pressure of the air injection.

Pressure stability

Pressure fluctuations can result in inconsistent bubble sizes, resulting in large, unstable bubble bubbles. High-precision pumps, such as those produced by Pincheng Motor, are meticulously designed to minimize pulsation and provide smooth airflow.

Quick response

In an automatic system, the pump must be able to reach the required pressure almost instantaneously. The powerful motor in the 12V DC mini diaphragm air pump can achieve rapid pressure establishment, thereby reducing the time for making beverages.

Silent design

For home and cafe environments, the pump must remain silent.High quality mini diaphragm pump low vibration design is very important to provide excellent user experience.

Pintown Motor: The precision behind the foam

Pincheng Motor is well aware that a perfect cup of coffee stems from precision.Our expertise in the field of micro pneumatics allows us to provide the key components that elevate the common coffee machine to a professional level. We specialize in developing diaphragm pumps that meet the demanding requirements of the food and beverage industry: Food grade materials: All components in contact with milk or air are made of food grade non-toxic materials to ensure hygiene, safety and compliance with relevant regulations. Custom Pressure curve: We work with coffee machine manufacturers to customize the flow and pressure characteristics of mini diaphragm pumps for their specific milk foam technology, whether it is a high flow small air diaphragm pump or a high vacuum mini diaphragm vacuum pump, we can meet the needs. Superior durability in high cycle environments: Our 12V mini diaphragm pumps are designed to meet the continuous high cycle needs of commercial applications, offering an extremely long service life and reducing maintenance costs.

conclusion

The secret to the perfect foam is precisely controlling the flow of air and milk, a task for which modern miniature pumps are perfectly equipped.Whether it is the positive pressure provided by the micro diaphragm air pump, or the controllable suction provided by the micro diaphragm vacuum pump, these small devices are indispensable.When choosing accessories for your coffee machine, choose a partner who can provide cafe-level precision, reliability, and customization.Choose Pinshing motor to meet your needs of 12V micro diaphragm pump, to ensure that every cup of coffee is perfect.

you like also all

Read More News

Post time: Nov-21-2025