Compare, select, buy your pump

050 Micro DC Motor 3V-7V High Speed for Shaver & Smart Home

Customized Service

To provide customers with quality products and satisfactory service

O50SAV Micro DC Motor

Integrating a reliable Small dc brushed Motor is essential for high-performance grooming electronics. For an Electric Shaver, the 050 model's high-speed rotation ensures a quick and efficient shaving experience without pulling. Its thin, flat profile allows manufacturers to design slimmer, more ergonomic handles. By using a Mini Brushed DC Motor, brands can achieve the perfect balance between high torque and low energy consumption, extending the battery life of portable personal care products.

Technical Specifications

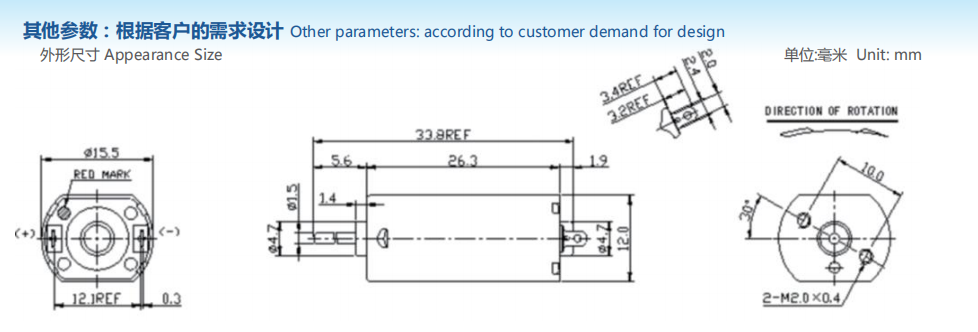

Specification Engineering Drawing

Product Applications

| Application Scenario | Key Benefit for the Design |

Recommended Input

|

| Audio & Visual Equipment (Car DVD/CD, Camcorders) | Precious metal-brush technology ensures low electrical noise and high reliability for precision playback mechanisms. |

2.5V - 6.0V Regulated DC

|

| Personal Care & Beauty (Face cleaners, Massagers) | Compact form factor (26.3mm length) fits slim, ergonomic handheld housings without sacrificing power. |

3.7V Li-ion Battery

|

| Security Products (Smart locks, Latches) | High Stall Torque (up to 50.0 g.cm) provides the necessary force to actuate mechanical locking pins reliably. |

6.0V - 7.0V Input

|

| Toys & Model Aircraft | High Power-to-Weight ratio (approx. 0.2-1.5W output) enables high-speed performance for micro-mechanisms. |

2.4V NiMH / 3.7V Li-po

|

Tea table

Vacuum packing machine

Water dispenser

Foam hand sanitizer

Electric decanter

dishwasher

Manufacturing Quality & Compliance

At Pinmotor, we prioritize rigorous quality control to ensure seamless integration into your high-volume production lines. Our manufacturing facility and the PYFP310-XG series comply with the most stringent global automotive and environmental standards:

ISO 9001:2015 Certified

Our quality management system ensures consistent product output, from raw material inspection to final functional testing of every foam pump.

IATF 16949 Compliant

We leverage automotive-grade process discipline to guarantee ultra-low defect rates and long-term reliability in consumer electronic applications.

RoHS & REACH Fully Compliant

All materials used in the 310G series—including the motor brushes, diaphragm, and housing—are free from hazardous substances, ensuring your end-product is ready for the EU and North American markets.

Technical Note: Full documentation, including material safety data sheets (MSDS) and compliance certificates, is available upon request for your engineering audit.

We supply more than just product, we engineer solutions optimised to suit your application requirements.

Q1: How does the flat design of the 050 Micro DC Motor benefit smart home devices?

A: The 050 Micro DC Motor features a unique flat shape with a thickness of only 10.0mm. This is a critical advantage for smart home applications like electronic locks or automated fragrance dispensers where internal space is extremely limited. The compact footprint allows for more sophisticated mechanical designs without increasing the overall size of the consumer product.

Q2: Why is a Precious metal brush motor for smart locks better than standard carbon brushes?

A: Using a Precious metal brush motor for smart locks ensures much lower electrical noise and more stable contact resistance. In smart security devices, this translates to higher reliability and a longer service life under low-current conditions. It also provides a faster response time, which is essential for the quick locking and unlocking mechanisms required in modern smart home ecosystems.

Q3: Can the RPM be customized for high-intensity beauty or medical massage tools?

A: Yes, while our standard models reach up to 14300RPM, we can adjust the internal winding and parameters according to specific customer demands. This customization ensures that the motor provides the exact vibration frequency or rotational force needed for professional-grade massagers, ensuring high efficiency without damaging the delicate components of the handheld device.