Advanced Engineering Plastics and Composites

High-Performance Polymer Selection

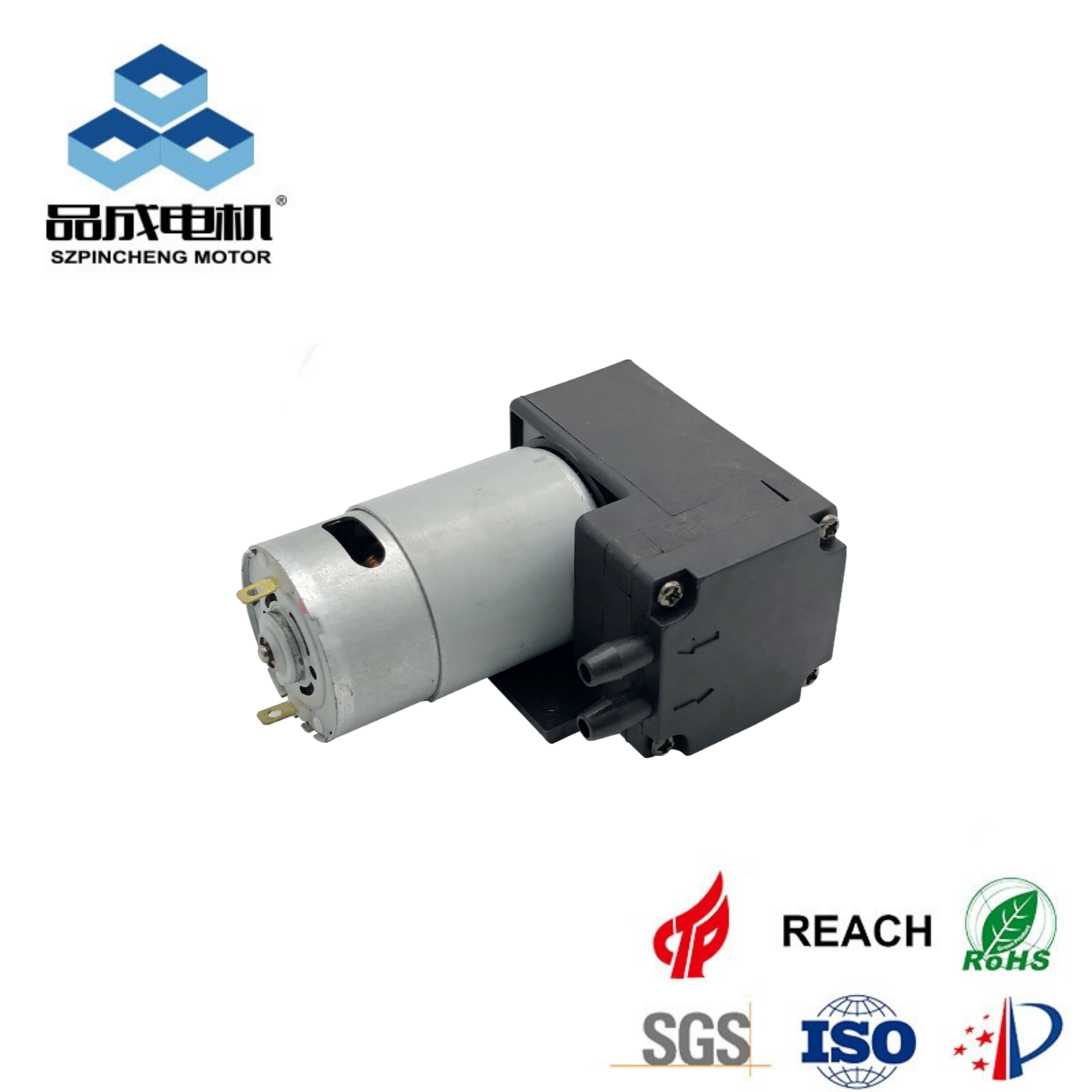

Pincheng's micro vacuum pump heads utilize engineering-grade polymers specifically chosen for their exceptional mechanical properties and chemical resistance. The primary housing components are manufactured from reinforced PTFE (Polytetrafluoroethylene) and PPS (Polyphenylene Sulfide), materials renowned for their stability under thermal stress and resistance to aggressive chemicals. This careful material selection ensures that Pincheng's 12v vacuum pump units maintain dimensional stability across a broad temperature range from -20°C to 80°C, far exceeding the capabilities of conventional plastic components.

Composite Material Innovations

What truly sets Pincheng's micro vacuum pump apart is their proprietary composite formulation that combines the best properties of multiple advanced materials. These custom-engineered composites deliver the structural strength of metals while maintaining the chemical resistance and weight advantages of high-performance polymers. The result is a low power vacuum pump head that withstands mechanical stress, chemical exposure, and thermal cycling without compromising performance or longevity.

Critical Wear Component Materials

Diaphragm Material Excellence

The diaphragm represents the heart of any micro vacuum pump, and Pincheng's approach to diaphragm material selection demonstrates their commitment to quality. While competitors use standard rubber or basic elastomers, Pincheng employs a proprietary triple-layer composite material specifically engineered for DC vacuum pump applications. This advanced material combination provides exceptional flex fatigue resistance, capable of withstanding over 10 million cycles without failure, while maintaining perfect sealing characteristics throughout its service life.

Valve and Seal Technologies

Pincheng's micro vacuum pump products feature precision-engineered valves manufactured from medical-grade stainless steel with elastomeric seals made from FKM (Fluoroelastomer) compounds. This material combination ensures perfect sealing even after extended periods of inactivity, a common failure point in lesser-quality pumps. The corrosion-resistant metals and chemical-resistant elastomers work in harmony to create 12v vacuum pump solutions that perform reliably in challenging environments where moisture, chemical vapors, or temperature extremes would compromise ordinary pumps.

Application-Specific Material Optimization

Medical and Laboratory Grade Materials

For healthcare and laboratory applications, Pincheng's micro vacuum pump products utilize USP Class VI certified materials and biocompatible components that meet stringent medical standards. The smooth, non-porous surfaces prevent bacterial colonization and allow for effective sterilization using common hospital disinfectants. This material superiority makes Pincheng's low power vacuum pump ideal for medical devices, diagnostic equipment, and laboratory instrumentation where material purity is non-negotiable.

Industrial Grade Durability

In industrial settings, Pincheng's DC vacuum pump heads are built with glass-fiber reinforced polymers and hardened stainless steel components that withstand the rigors of continuous operation in demanding environments. These materials resist abrasive particles, chemical splashes, and mechanical impacts that commonly occur in manufacturing and automation applications. The robust construction ensures that Pincheng's micro vacuum pump units deliver consistent performance in conditions that would quickly degrade inferior products.

The Pincheng Material Advantage

Long-Term Reliability Through Material Science

Pincheng's sophisticated approach to material selection directly translates to extended service life and maintained performance. Their micro vacuum pump products demonstrate remarkable resistance to the common failure modes that plague conventional pumps – material degradation, wear particle generation, and gradual performance decline. This material excellence means that Pincheng's 12v vacuum pump typically operates reliably for thousands of hours longer than competitive models, providing superior long-term value.

Consistent Performance Across Conditions

The stability of Pincheng's chosen materials ensures that their DC vacuum pump products deliver consistent vacuum performance regardless of operating conditions. Unlike pumps that suffer from material expansion/contraction with temperature changes or chemical degradation from exposure to process media, Pincheng's carefully selected materials maintain their properties across a wide range of environmental conditions. This consistency is particularly valuable in applications where process stability directly impacts product quality or operational safety.

Quality Assurance and Material Verification

Rigorous Material Testing Protocol

Every material used in Pincheng's micro vacuum pump production undergoes comprehensive testing and verification. Incoming raw materials are subjected to mechanical, chemical, and thermal testing to ensure they meet strict specifications. Component-level testing verifies performance under simulated operating conditions, while finished products undergo final validation to guarantee they will perform as promised in real-world applications. This multi-layer quality assurance process ensures that every Pincheng low power vacuum pump delivers the material performance customers expect.

Environmental Compliance and Sustainability

Pincheng demonstrates industry leadership through their commitment to environmental responsibility in material selection. All micro vacuum pump materials comply with RoHS directives and REACH regulations, and the company continuously explores sustainable alternatives that maintain performance standards. This forward-thinking approach ensures that Pincheng's DC vacuum pump products not only excel in performance but also align with modern environmental standards and corporate sustainability goals.

you like also all

Read More News

Post time: Oct-10-2025