Invisible heartbeats: a practical guide to choosing the right 12V miniature diaphragm pump

When you enjoy a fashionable coffee machine, a modern water dispenser, or a life-saving medical device, you rarely think of drive the flow of fluid in the tiny parts.However, the performance, reliability, and even service life of the entire product often depend on the quality of this small pump.Choose the appropriate 12 v mini diaphragm pump is not easy;It requires a deep understanding of the unique needs of the application scenario, a keen eye for materials science and, frankly, some industry experience.This choice can make the difference between a market-leading product and a disappointment.

Three application areas: coffee, drinking water, and medical

We usually categorize pumps by technology, but in terms of choice, I think it's more effective to categorize pumps by their use.Water pump of the coffee machine and water dispenser pump or medical equipment are entirely different.

1. Coffee machine challenges: precision and heat resistance

In a coffee machine, water pump's mission is to accurate delivery, and often need to run under the environment of high temperature. Its key requirements include: Thermal stability: the pump must be able to bear high temperature and material degradation does not occur.This means selecting high temperature resistant miniature diaphragm pumps with seals and diaphragms made of materials such as EPDM or specific food-grade silicone.

• Flow accuracy: Consistency is essential in the coffee brewing process.The water pump needs to deliver the precise amount of water required for a single cup or a whole pot of coffee in each cycle.Pulsations must be minimized to ensure smooth and even flow of water through the heating element.

• Food grade compliance: any parts that come into contact with drinking water must meet strict international standards (e.g. FDA or LFGB).Food grade micro diaphragm pump is essential.

2. Essential elements of water dispenser: reliability and silent operation

Whether in the office or at home, water machine is the most important points: mute and durability.

• Acoustic engineering: No one wants noisy pumps to disturb their work or home environment.Therefore, the design of low noise micro diaphragm pump is very important.It's not just a simple damping treatment;It also requires precise balance of motor and optimize the flow channel, to minimize cavitation and mechanical vibration.

• Working cycle: These pumps are typically running for long periods of time, hence the need for continuously running miniature diaphragm pumps.The motor must be strong and durable, is usually a brushless dc motor, able to run for a long time to avoid overheating or brush premature wear.

3. Necessity of medical application: safety and precision

In medical applications, especially the importance of water pump.In these applications, pumps are often a critical component in diagnostic, therapeutic, or patient care equipment.

• Chemical compatibility: Pumps for diagnostic analyzers must be able to handle aggressive reagents without corrosion.This usually requires the use of chemically resistant micro diaphragm water pumps, whose wet parts are made of polytetrafluoroethylene (PTFE) or Kalrez materials.

• Regulatory compliance: In addition to performance, manufacturers must also provide complete material traceability and comply with quality management systems (e.g. ISO 13485).The quality of the medical level micro diaphragm pump depends not only on its performance, also depends on the documentation and quality control. Reliability, life support: for portable devices such as dialysis or patients cooling system, the pump must be high reliability of miniature diaphragm pumps.Any fault is absolutely not allowed.

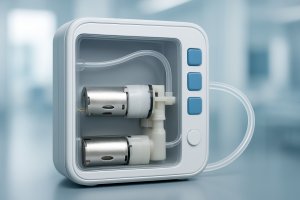

What makes Pincheng unique: Engineering beyond standard spec sheets

At Pincheng Motor, we not only produce pumps but are also committed to tailoring fluid solutions for these harsh environments.When you choose a small diaphragm pump, you're not just buying a component, you're buying an investment in a partnership that understands the nuances of your end product. We've seen countless projects where seemingly good pumps end up failing because engineers have overlooked subtle points -- for example, a micro diaphragm pump that is rated at 12V but can't withstand the system's voltage spikes;Or, the pump material, although food-grade, fails at the high temperatures of the coffee machine cleaning cycle. Our approach is quite different.

We focus on the long-term requirements that truly define success:

• Custom pressure curves: We don't just provide standard flow rates.We can adjust the internal structure of the pump and the motor drive to achieve the exact pressure curve required by your coffee machine, so as to obtain the best extraction results;Or achieve the precise flow stability your medical device needs.

• Acoustic optimization: Our micro diaphragm pump design incorporates advanced acoustic damping technology to ensure that our pump is one of the quietest in the industry -- a critical factor for any micro diaphragm pump for use in bedside equipment.

• Material certification: We provide verifiable and traceable material certification.

Recommend products

Read More News

Post time: Nov-28-2025