Compare, select, buy your pump

High Torque 4260 BLDC Motor with 42mm Planetary Gearbox | 12V 24V Custom Options | PinMotor

Customized Service

To provide customers with quality products and satisfactory service

PC-PM42-BL4260 DC Gear motor

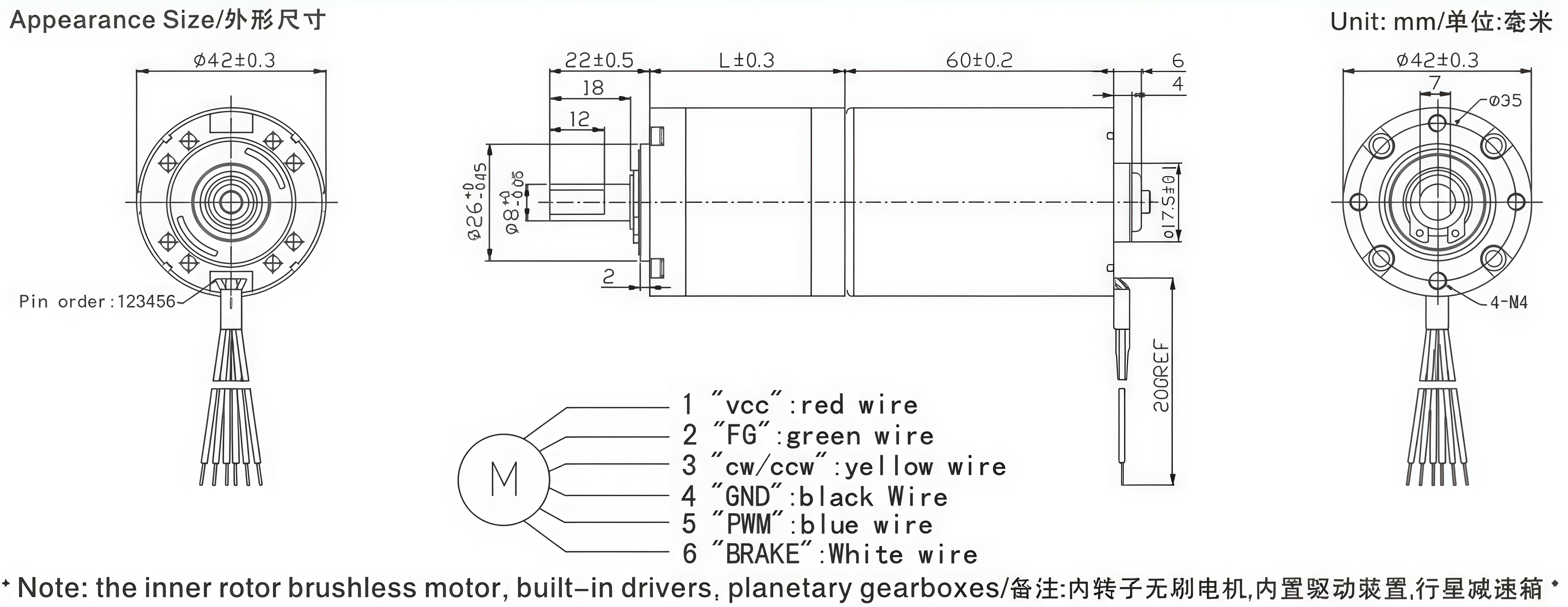

Upgrade your systems with our Precision Reduction Motor, engineered for accuracy and longevity. In Smart Home Automation, this Low noise BLDC motor for smart home provides a seamless experience for motorized curtains and automated windows. Its built-in 6-pin wiring interface—including PWM speed control and FG signal feedback—allows for sophisticated integration into centralized home hubs.

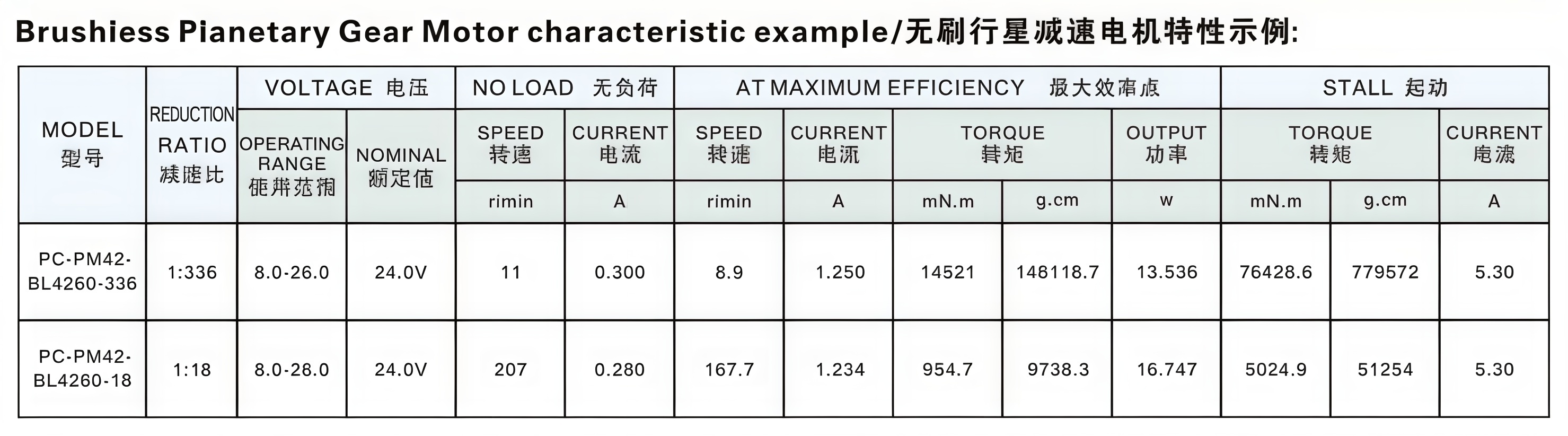

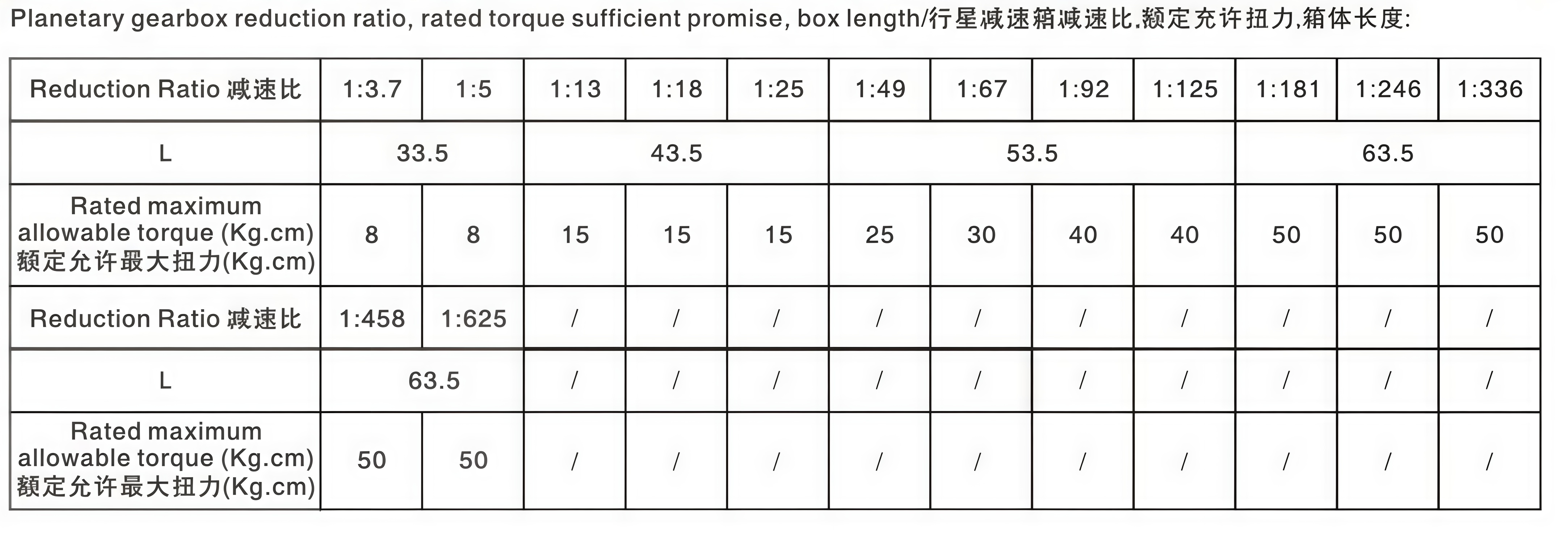

Technical Specifications

Specification Engineering Drawing

Product Applications

| Application Scenario | Key Benefit for the Design | Recommended Input |

| Solar Tracking Systems | High torque brushless planetary motor 24V provides a massive stall torque of up to 779,572 g.cm to withstand heavy wind loads. | 24V DC Stable Power |

| Smart Home Automation | Low noise BLDC motor for smart home featuring an inner rotor design and planetary gearbox for quiet, smooth operation in residential environments. | 12V - 24V DC |

| AGV Robot Drive | Industrial grade planetary gear motor 12V offers high stall current (5.30A) for high-inertia starts in automated guided vehicles. | 12V - 24V Li-ion Battery |

| Precision Medical Devices | Precision planetary gearbox with 42mm BLDC ensures accurate positioning and rapid stopping via the integrated brake wire. | 24V Regulated Power |

| Industrial Actuators | 4260 BLDC Motor with a wide operating range (8.0V-26.0V) ensures consistent performance across various industrial voltage standards. | 8V - 26V DC |

Tea table

Vacuum packing machine

Water dispenser

Foam hand sanitizer

Electric decanter

dishwasher

Manufacturing Quality & Compliance

At Pinmotor, we prioritize rigorous quality control to ensure seamless integration into your high-volume production lines. Our manufacturing facility and the PYFP310-XG series comply with the most stringent global automotive and environmental standards:

ISO 9001:2015 Certified

Our quality management system ensures consistent product output, from raw material inspection to final functional testing of every foam pump.

IATF 16949 Compliant

We leverage automotive-grade process discipline to guarantee ultra-low defect rates and long-term reliability in consumer electronic applications.

RoHS & REACH Fully Compliant

All materials used in the 310G series—including the motor brushes, diaphragm, and housing—are free from hazardous substances, ensuring your end-product is ready for the EU and North American markets.

Technical Note: Full documentation, including material safety data sheets (MSDS) and compliance certificates, is available upon request for your engineering audit.

We supply more than just product, we engineer solutions optimised to suit your application requirements.

Q1: What are the main advantages of using a planetary gearbox with a 4260 BLDC motor?

A: The planetary gearbox design offers a higher torque-to-volume ratio compared to spur gearboxes. It uses multiple gear contact points to distribute the load, resulting in increased durability and the ability to handle higher radial and axial loads. Combined with a 4260 brushless motor, this setup provides a high-efficiency (up to 90%), compact, and quiet power solution for precision-heavy applications.

Q2: Can I get a customized gear ratio and output shaft for my project?

A: Yes, as a professional brushless motor manufacturer, Pincheng offers full OEM/ODM customization. We can adjust the gear ratio (from 3.7:1 to over 719:1) to achieve your specific speed and torque requirements. We also provide custom shaft designs, including D-cut, keyed, threaded, or cross-hole shafts in various lengths.

Q3: How do I control the speed and direction of the 4260 brushless motor?

A: Our 42mm BLDC motors typically come with a 5-wire or 8-wire interface. You can control the speed via PWM (Pulse Width Modulation) or a 0-5V analog signal. Direction (CW/CCW) is easily toggled by connecting the direction wire to high or low voltage. We also offer versions with integrated drivers for “plug-and-play” simplicity.

Q4: What is the expected lifespan of this planetary gear motor?

A: Thanks to the brushless (BLDC) technology, there are no brushes to wear out. The lifespan is primarily determined by the high-quality ball bearings and the gear material. Under rated operating conditions, our 4260 motors typically exceed 20,000 hours of operation, significantly outlasting traditional brushed DC motors.