The advantage of miniaturization is its quiet, inconspicuous nature.However, for many users, the experience is often marred by unexpected and annoying noises. Why is the micro air pump so noisy?This question is often asked, especially in applications such as medical devices, aromatherapy machines or portable electronics that require very high levels of silence.This article delves into the root causes of noise in these small devices and explains how manufacturers such as Pinsent Electric have engineered a truly small and silent air pump.

The Three Primary Sources of Air Pump Noise

Noise in a miniature air pump is not a single phenomenon, but a combination of three different sound sources: mechanical, pneumatic, and electrical.

1. Mechanical Noise: The Motor and Moving Parts

At the heart of any micro-pump is a DC motor, which operates to generate noise through vibration.

• Motor vibration: Motor rotor imbalance or bearing wear can cause the entire pump housing to vibrate, just like a small speaker.This is usually a low-frequency hum or quack sources.

• Component friction: In the diaphragm pump, the rapid movement of the linkage and the bending of the diaphragm itself produce a clicking or tapping sound.

Installation: if the 6 v micro air pump firmly installed on hard surface, the noise will be amplified and spread over the whole equipment shell.

2. Pneumatic Noise: The Air Itself

This is the sound of air flowing through the pump and system.

• Pulsation in/out air: Air is sucked in and expelled in discrete pulses, producing a fast "puffing" sound.This pulsation is particularly pronounced in small air vacuum pumps where the air is rapidly compressed or evacuated.

• Turbulence: High frequency whistling or hissing sounds as air rushes through small, sharply angled ports and pipes.

3. Electrical Noise: The Motor Commutation

In a brushed DC motor, the commutation process (where the brush switches current to the motor windings) produces high-frequency electrical noise that is sometimes audible or can interfere with sensitive electronics.

Troubleshooting: Making Your Micro Pump Quieter

Before replacing the pump of excessive noise, a few simple steps usually can significantly reduce the noise.

• check installation: pump firmly installed?Using a soft rubber gasket or a dedicated sound-absorbing foam between the miniature air pump (6V) and the enclosure of the device absorbs mechanical vibrations, turning loud clicks into soft whispers.

• Check the piping: make sure the piping is not bent or rubbing against the equipment wall.Bending increases the back pressure, forcing the pump to work harder, which creates more noise.

• Filter air: Blocked intake filters can cause insufficient air supply to the air pump, making it difficult to operate and producing excessive noise.Cleaning or replacing filters regularly is a simple maintenance step.

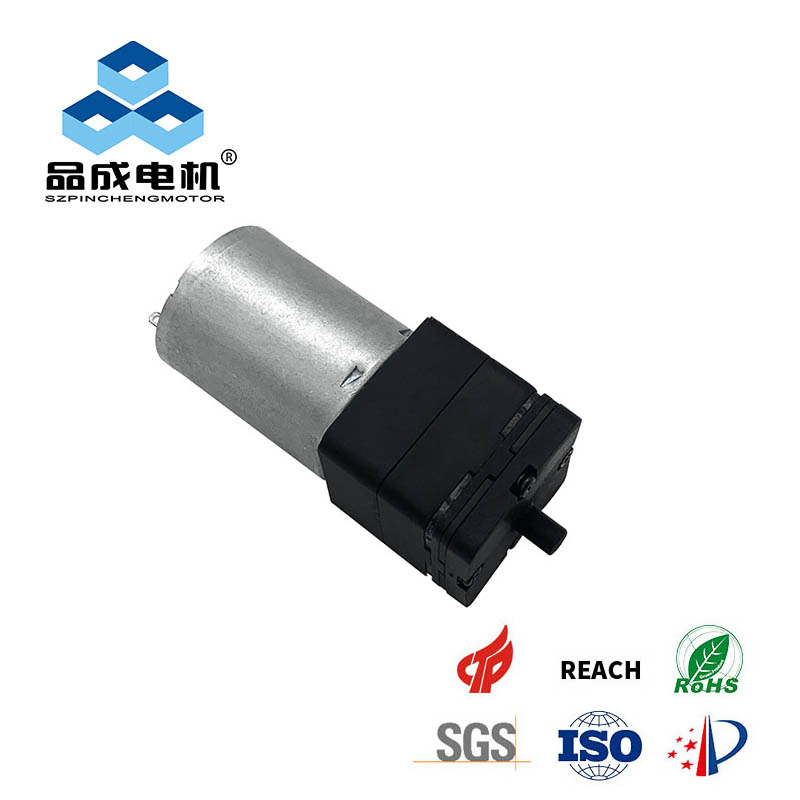

Pincheng Motor: Engineering the Small Quiet Air Pump

At Pincheng, we know that noise is a key factor affecting product quality.Our design philosophy, with superior acoustic performance at its core, ensures that our pumps are not only powerful, but also virtually silent.What we build is not just a miniature vacuum pump, but a silent solution.

Acoustic damping materials: we in the pump casing and installed base adopts special, high density and low springback materials, to absorb and isolation of mechanical vibration, make our products is in itself a small quiet air pump.

• Precision motor balancing: Our motors are rigorously balanced to eliminate rotor imbalance, which is the main source of low-frequency hum.

Optimization of air flow dynamics: we use the advanced computational fluid dynamics (CFD) technology, design a smooth, optimization of airway and port, minimize turbulence and the resulting aerodynamic noise.

• Custom solutions: For highly sensitive applications, we provide custom acoustic enclosures and custom flow curves to ensure that the pump operates at the most efficient and quiet in your specific 6V micro air pump application.

Conclusion

Why are miniature air pumps so noisy?The answer lies in the complex interplay between mechanical and aerodynamic forces within its tiny size.Although noise is an inherent component of any motor system, it is not an unavoidable defect.By understanding noise sources and applying advanced engineering principles, manufacturers can create truly small, silent air pumps.When choosing the next component, might as well choose partners, such as product if motor excellent acoustic performance is its standard configuration, to ensure that your products at the same time of providing high performance, avoid unnecessary noise.

you like also all

Read More News

Post time: Nov-24-2025