In the high-stakes world of medical devices, industrial automation, and precision fluid control, motor longevity is more than just a spec—it is a critical factor in system reliability and Total Cost of Ownership (TCO). As industries transition from traditional brushed motors to Brushless DC (BLDC) technology, understanding the true service life of these components is essential for engineering success.

This guide explores the typical lifespan of BLDC motors, the technical factors that influence durability, and how to maximize the MTBF (Mean Time Between Failures) in your application.

1. Brushed vs. BLDC Motor: The Life Expectancy Gap

The most frequent question engineers ask is: “How much longer will a brushless motor last compared to a brushed one?”

In a traditional brushed motor, physical contact between carbon brushes and the commutator creates friction, sparking, and electrical erosion. This mechanical wear typically limits the motor's life to 500 – 2,000 hours.

In contrast, BLDC motors utilize electronic commutation, eliminating the primary wear-out mechanism.

Quick Comparison Table

| Feature | Brushed DC Motor |

Brushless DC (BLDC) Motor

|

| Typical Lifespan | 500 – 2,000 Hours |

10,000 – 20,000+ Hours

|

| Main Failure Point | Brush/Commutator Wear |

Ball Bearings / Controller Fatigue

|

| Maintenance | High (Brush Replacement) |

Zero Maintenance

|

| Efficiency | 70% – 80% | 85% – 95% |

| Best For | Low-cost, intermittent use |

Mission-critical, 24/7 operation

|

2. Key Factors Determining BLDC Motor Longevity

While BLDC technology is inherently more durable, it is not immortal. To accurately project the lifespan of a motor, three technical pillars must be evaluated:

A. Bearing Quality (The Mechanical Limit)

Since there are no brushes, the bearings are usually the first component to fail. Whether using sleeve bearings or high-precision ball bearings, they eventually face lubricant degradation or metal fatigue. High-end BLDC motors use shielded stainless steel ball bearings rated for tens of thousands of hours.

B. Thermal Management & Winding Integrity

Heat is the silent killer of electric motors. Excessive temperatures can:

-

Break down the insulation on copper windings, leading to short circuits.

-

Cause permanent demagnetization of the rotor magnets. A motor running 10°C cooler can potentially double its insulation life.

C. Electronic Component Robustness

The "brain" of a BLDC motor—the ESC (Electronic Speed Controller)—contains MOSFETs and capacitors. The quality of these semiconductors, especially when integrated into the motor housing, dictates whether the electronics will outlast the mechanical parts.

3. How to Maximize Your Motor’s Service Life

To reach the upper limit of the 20,000-hour benchmark, consider these integration best practices:

-

Operate at the "Sweet Spot": Avoid running motors at 100% rated torque continuously. Operating at 70-80% of rated capacity significantly reduces thermal stress.

-

Optimize the Duty Cycle: While BLDC motors excel at continuous motion, allowing for thermal stabilization prevents heat soak.

-

Environmental Ingress Protection (IP Rating): Ensure your motor has the correct IP rating for its environment. Dust and moisture are the leading causes of premature bearing failure.

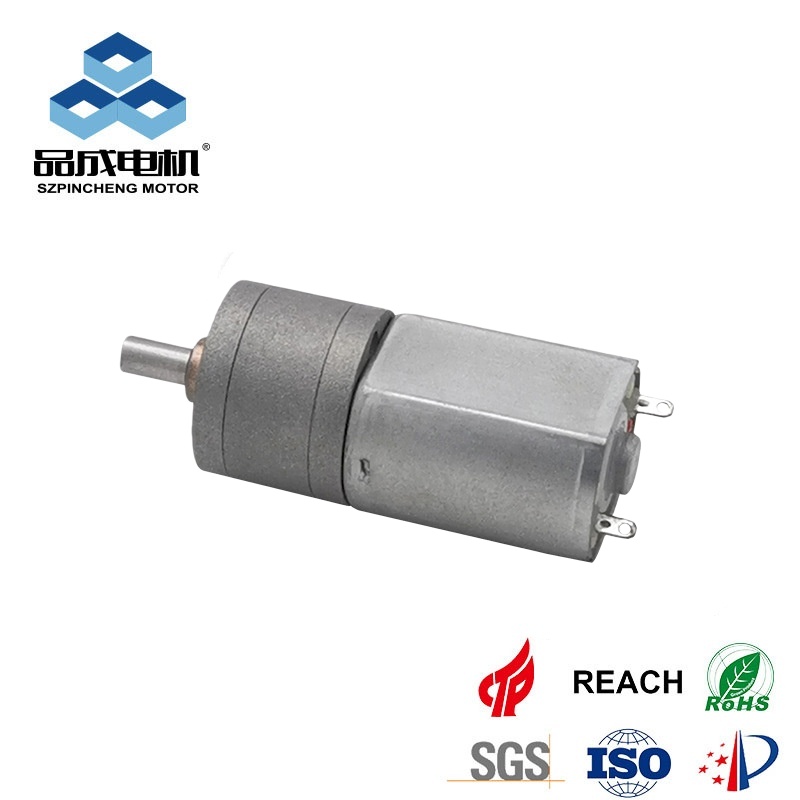

4. Why PinMotor is the Standard for High-Reliability BLDC Solutions

At PinMotor, we don't just manufacture motors; we engineer long-term motion solutions for critical fluidic and mechanical systems. Our BLDC series is designed to exceed industry standards through:

-

Premium Bearing Selection: We source only high-grade, precision ball bearings to ensure the mechanical foundation matches our electronic durability.

-

Advanced Thermal Dissipation: Our housings are engineered with high-thermal-conductivity materials and optimized geometry to shed heat faster than standard designs.

-

Rigorous ALT (Accelerated Life Testing): We simulate years of field use in our labs, identifying potential failure modes before the product ever reaches your assembly line.

FAQ: Frequently Asked Questions about BLDC Reliability

Q: Can a BLDC motor last 50,000 hours?

A: Yes. In clean, temperature-controlled environments with light loads and premium bearings, some BLDC motors can exceed 50,000 hours. However, 10,000-20,000 is the standard conservative estimate for industrial use.

Q: What is the most common cause of BLDC failure?

A: Bearing failure due to contamination or lack of lubrication is the #1 cause, followed by electronic failure due to voltage spikes or overheating.

Q: Does motor speed (RPM) affect lifespan?

A: Absolutely. Higher RPMs increase the wear rate on bearings and generate more heat. Choosing a motor with higher torque at lower speeds often extends the total service life.

Ready to Optimize Your System’s Reliability?

Choosing the right motor is a balance of performance, size, and longevity. At PinMotor, our engineers provide data-driven lifespan projections to help you build better products.

[Contact our Engineering Team] for a custom reliability analysis

[Browse our BLDC Product Catalog] to find the perfect fit for your next project.

Recommend products

Read More News

Post time: Jan-22-2026